- PVC Machines

- Profile Processing & Cutting Centers

-

Products

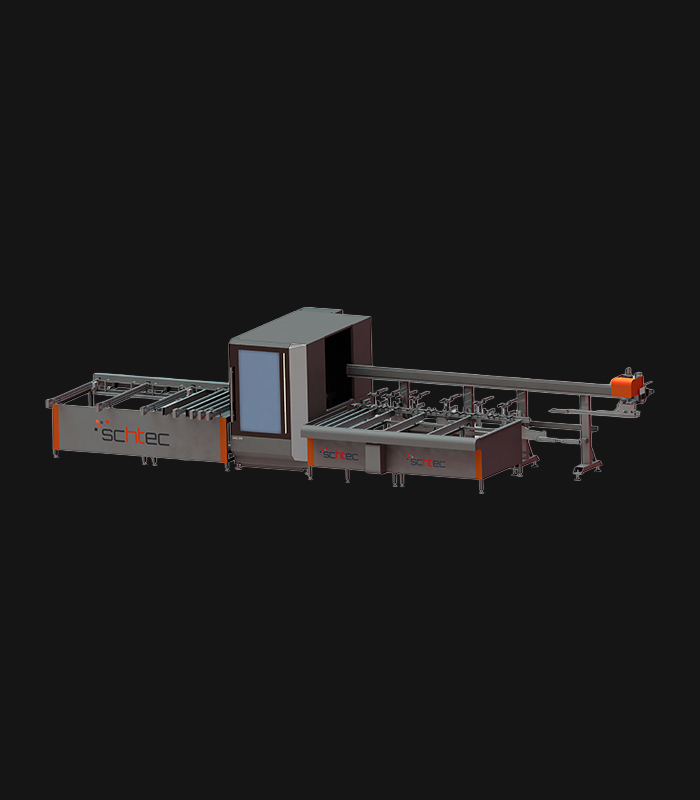

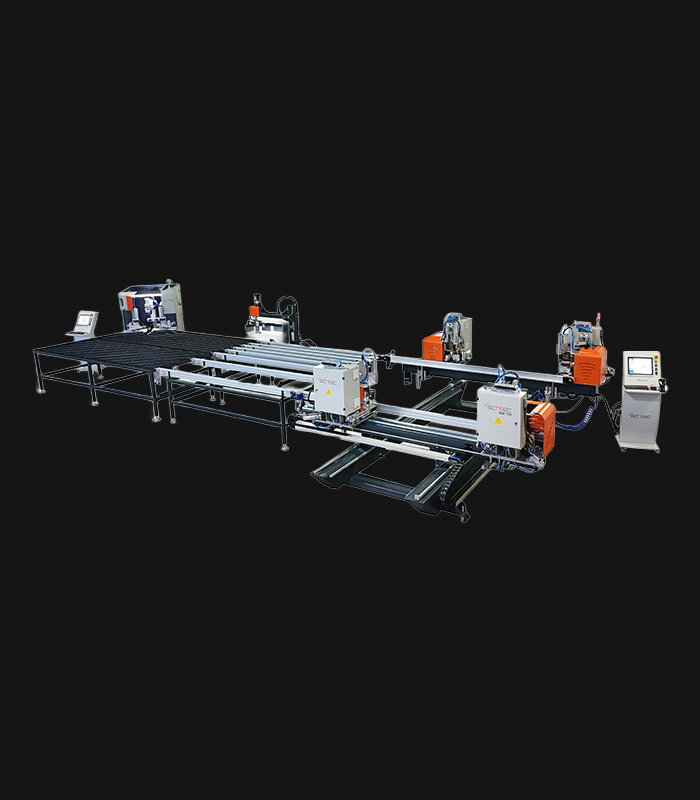

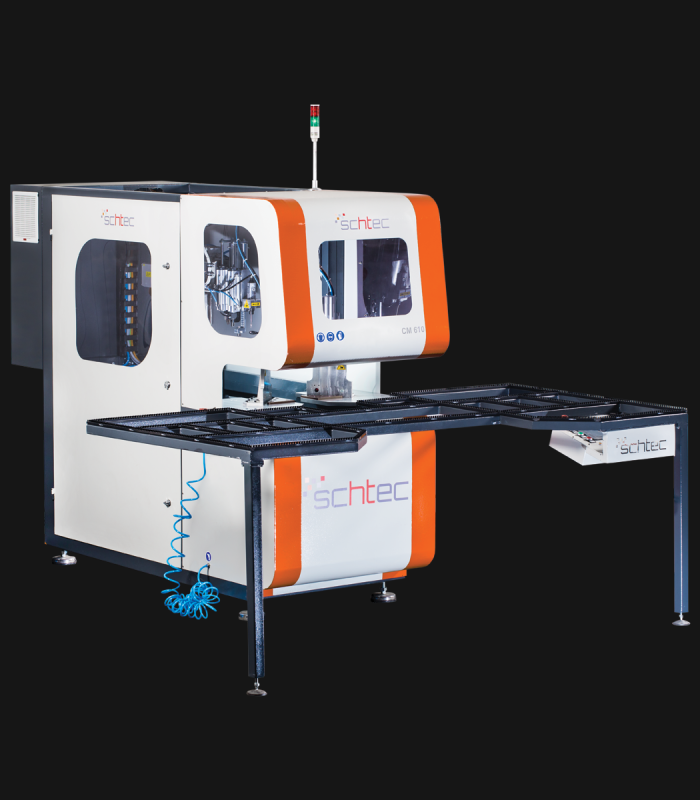

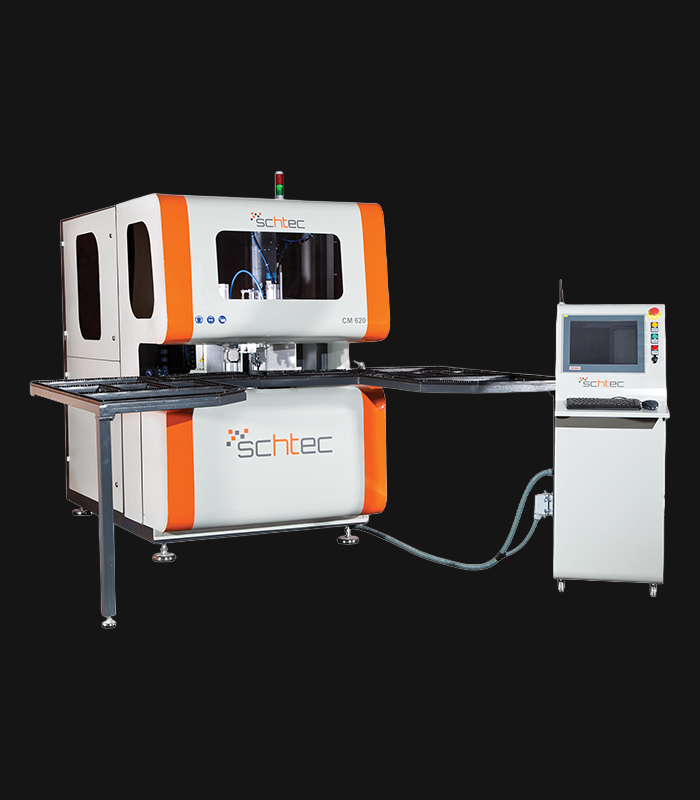

- SMC 360 PVC Profile Processing & Cutting Center

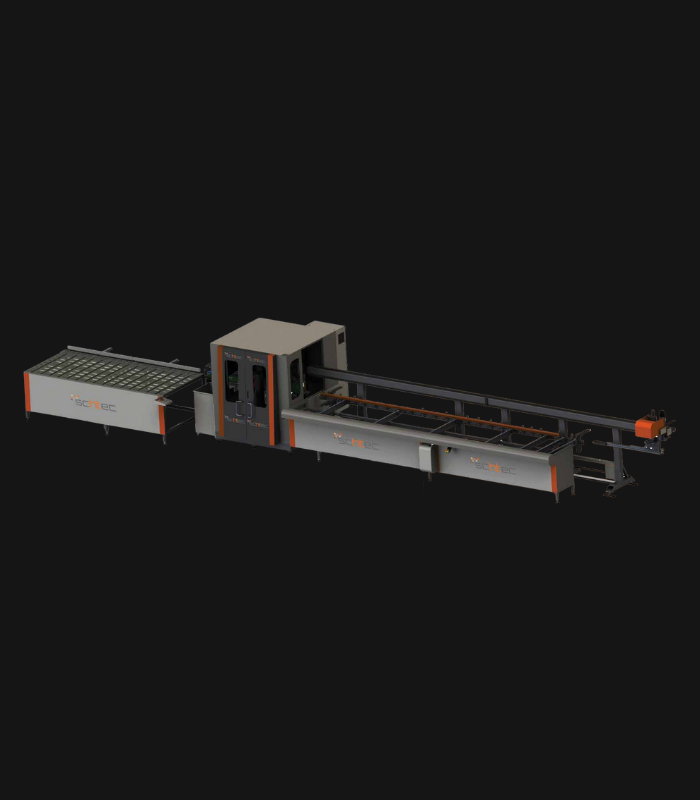

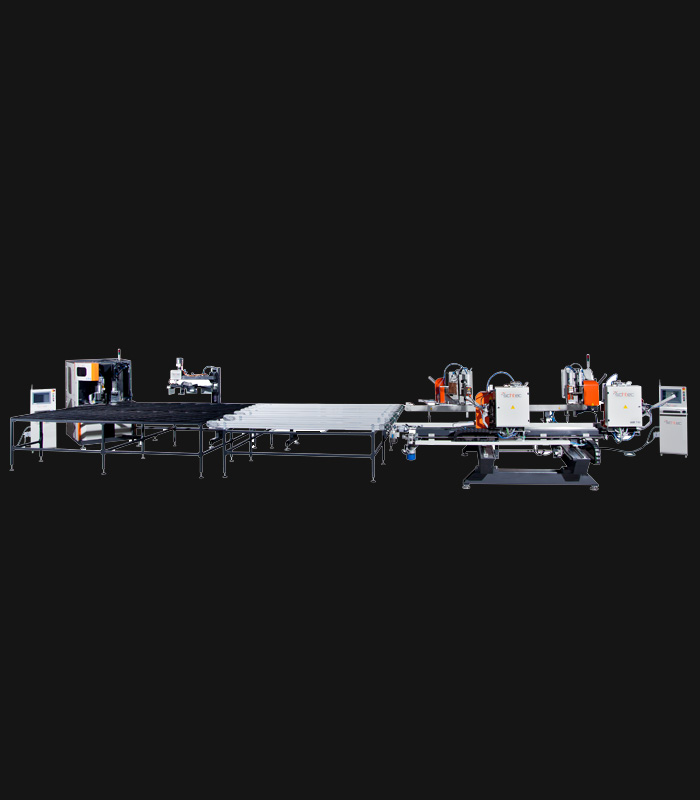

- SMC 320 PVC Profile Processing & Cutting Center

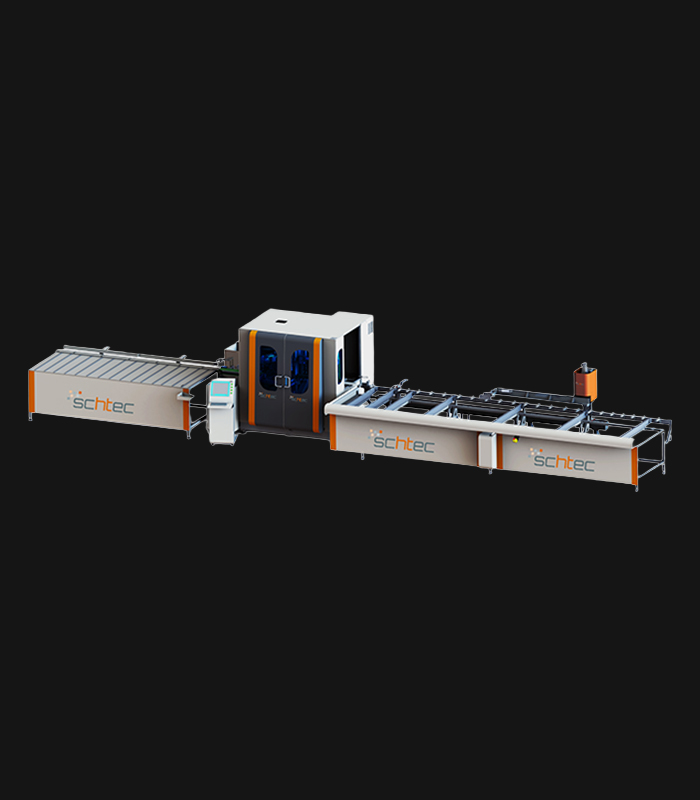

- SMC 310 PVC Profile Processing & Cutting Center

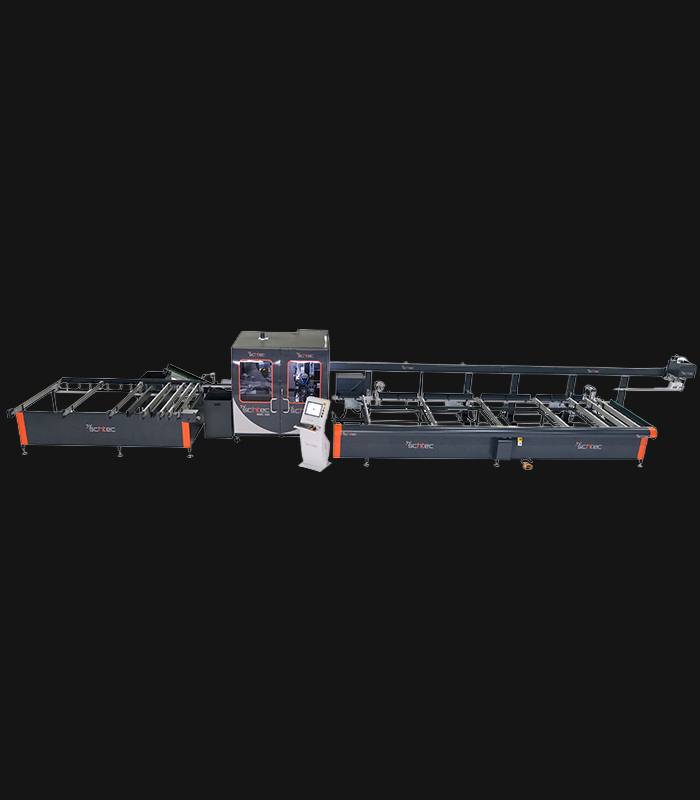

- SMC 308 PVC Profile Processing & Cutting Center

- SMC 305 PVC Profile Processing Center

- SVMC 120 Profile Processing & V-Type Cutting Center

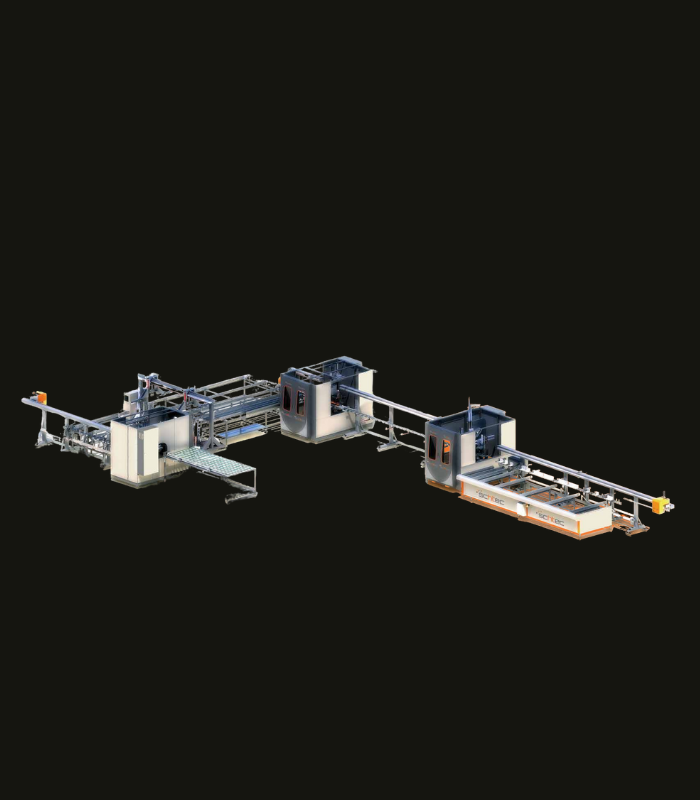

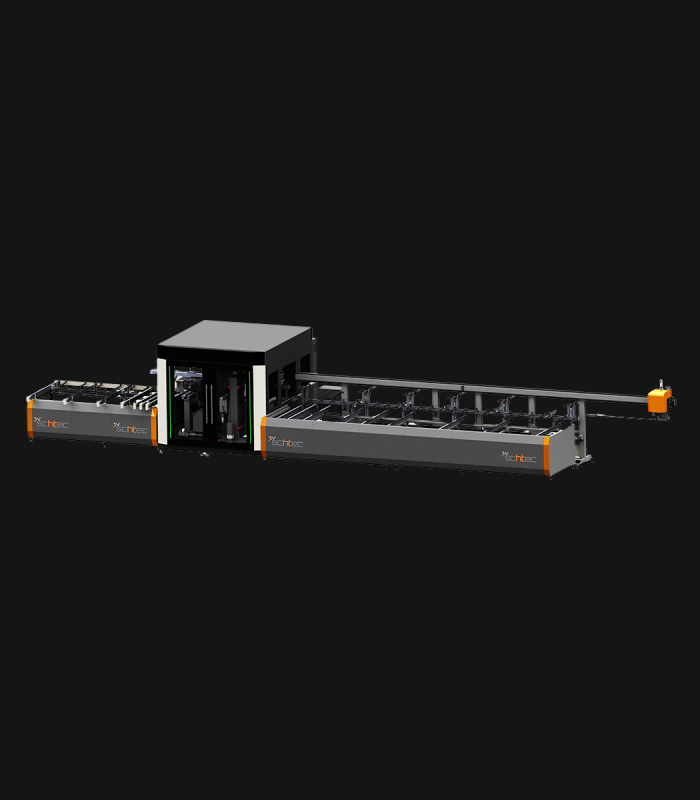

- CSML 240 Fully Automated Processing Center

-

Products

- Cutting Machines

-

Products

- DCA 460 Double Head Aluminium & PVC Cutting Machine

- DCA 435 Double Head Aluminium & PVC Cutting Machine

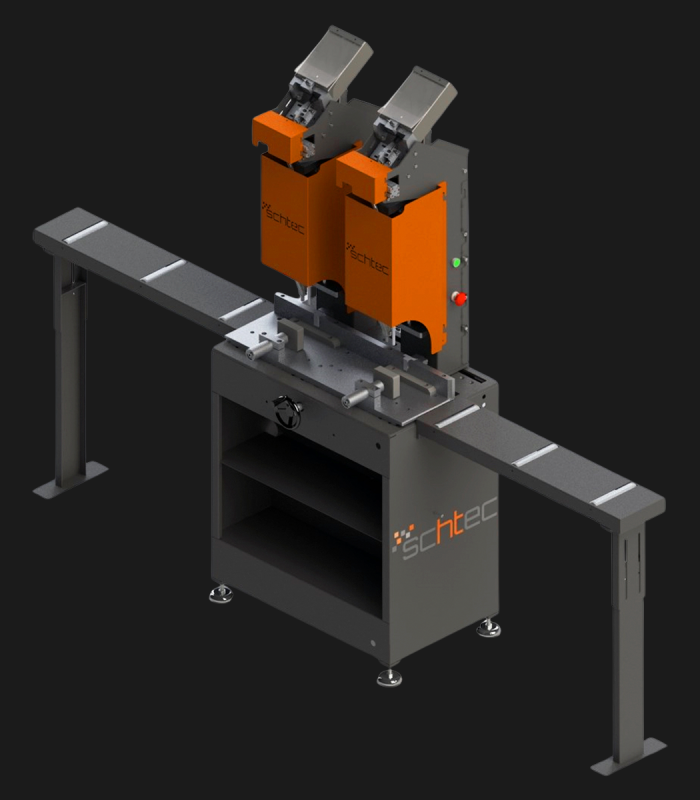

- SD 140 Double Head PVC & Aluminium Cutting Machine

- SS 110 Single Head PVC & Aluminium Cutting Machine

- SG 100/110 PVC Glazing Bead Saw

- SG 100 + MA 270 + MD 272 Electronic Digital Measuring Device

- SG 110 + MA 270 + MD 272 Electronic Digital Measuring Device

-

Products

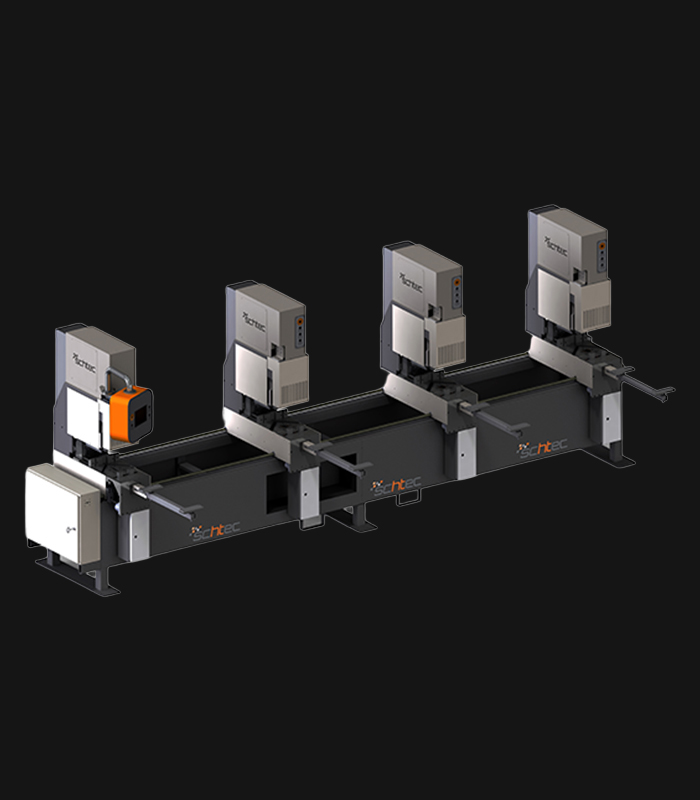

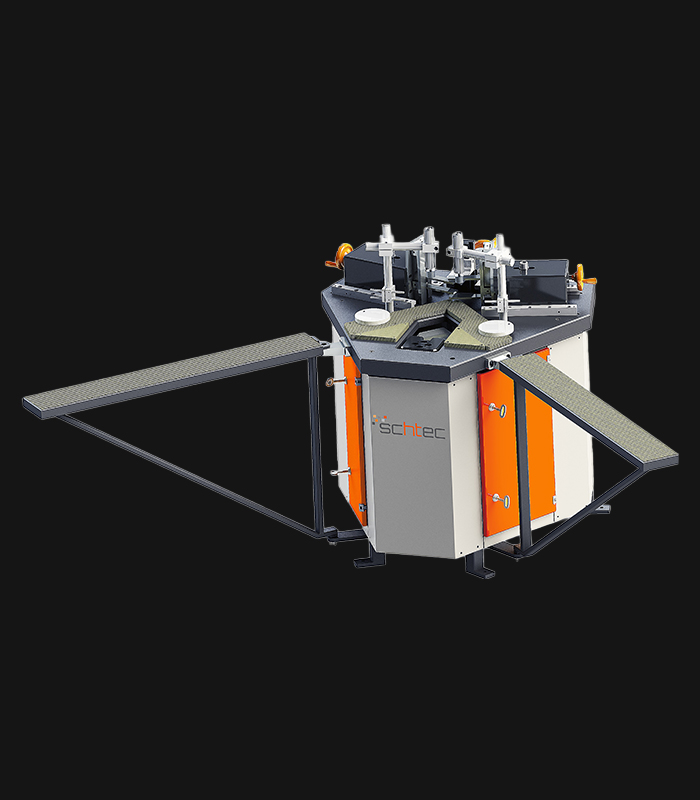

- Four Head Welding & CNC Corner Cleaning Line

- Welding Machines

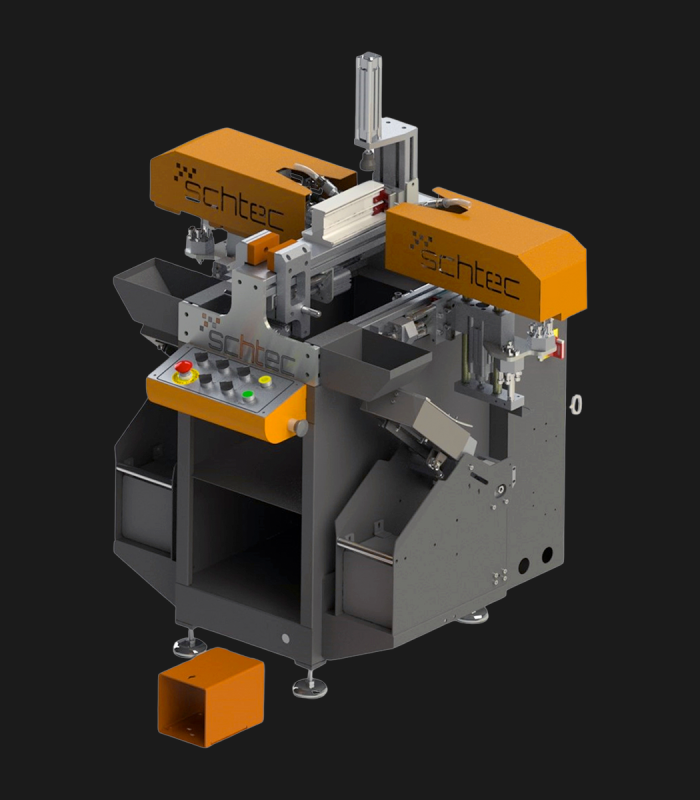

- Copy Router & Drilling Machines

- End Milling Machines

- Fully Automatic Profile Screwing Centers

- Screwing & Reinforcement Machines

- Corner Cleaning Machines

- Assembly Machines

- Profile Processing & Cutting Centers

- Aluminium Machines

- Services

- Corporate

- Contact us