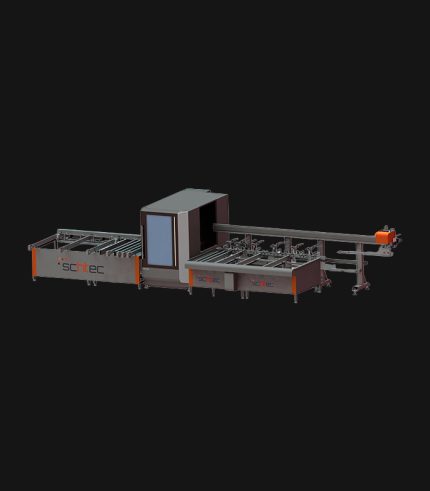

SMC 310 Profile Machining & Cutting Center

SCHTEC SMC 310: CNC for PVC & aluminum, 0.1° saw precision, 30°-150° cuts, synchronized milling. Supports 6.5m profiles, 8 at once. 9.8 kW, 15” touchscreen.

SMC 310 Technical Specifications

| Voltage | 400 V, 3 Ph, 50-60 Hz |

| Power Consumption | 9.8 kW, 24.5 A |

| Max. Profile Height | 120 mm |

| Min. Profile Height | 40 mm |

| Max. Profile Width | 130 mm |

| Min. Profile Width | 35 mm |

| Max. Profile Bar Length | 6,500 mm |

| Max. Processing Length | 6,000 mm |

| Maximum Cutting Length | 3,000 mm (can be increased if needed) |

| Minimum Cutting Length | 370 mm |

| Minimum Process Length for Profile | 1,200 mm |

| Tool Diameter | 6 mm Carbide Fast Tool |

| Tool RPM | 18,000 rpm |

| Max. Axes Speed (Processing) | 50 m/min |

| Max. Axes Speed (Saw) | 100 °/sec |

| Max. Axes Speed (Carrier) | 40 m/min |

| Air Pressure | 6-8 bar |

| Air Consumption | 650 l/min |

| Machine Height | 2,178 mm |

| Machine Width | 2,860 mm |

| Machine Length | 13,325 mm |

| Machine Weight | 3,500 kg |

| Standard Tool Count | 6 high-speed air-cooled spindles |

SMC 310 Profile Machining and Cutting Center

Standard Features

- This 3 axes controlled CNC processing center can do all operations on PVC profiles such as cutting, marking, opening key holes, copy routing for water slot milling, hinge holes, handle holes etc.

- All angles between 30 – 150 degrees are cut with 0.1 degree accuracy servo axis controlled 500 mm diameter saw.

- Routing and cutting processes are synchronized to run at the same time

- With the processed profile, 8 pieces can be loaded on the machine. (Max.length 6.5 m)

- Private HMI software developed by Schtec Software Departmant allows different kinds of window design program data files to be uploaded on machine.

- Optimisation option can be enabled for each projects seperately therefore machine makes optimisation for waste profiles automatically.

- All alarms and machine faults are displayed on HMI along with solutions

- 15” Touch Screen and high performance industrial PC with Windows XP Embeded system. This system can operate fanless between 0°C and 55°C.

- Industrial PC Based Servo Control System (Beckhoff)

- Online diagnostic and troubleshooting via user friendly interface.

- File transfer by USB or ethernet network and remote desktop connection by WiFi or Ethernet connection

- Central lubrication system reduces the time spent on maintanence

- Automatic dust collection system sucks out all pvc dusts and removes wastes fast with 2 different carriers

Optional

- Optional screwing station having two screw units allows simultaneous screwing of reinforcement steel via servo controlled axes system.

- For operations which can be done on profiles with a height greater than 120 mm and maximum cutting height, please inquire to us

Designed for medium-scale production lines, the SCHTEC SMC 310 automates cutting, drilling, and milling of PVC and aluminum profiles. It features a 500 mm saw blade with 0.1° precision and angled cuts between 30° and 150°. Its CNC-controlled milling unit handles handle slots, locks, and cylinder holes with high accuracy. The elevator loading system supports up to 6.5 meters and eight profiles, ensuring continuous production. A 15” touchscreen with SCHTEC software offers full control and user-friendly operation. With 9.8 kW of motor power, the SMC 310 increases speed without sacrificing quality.

PVC & Aluminium Profile Machining and Cutting Center

SCHTEC SMC 360, MCCALL'S 650, SVMC 120: CNC for PVC & aluminum, 0.1° precision, 6.5m capacity. Automate window & door production. Get a quote!

FAQ

What is a PVC profile machining center and what is it used for?

SCHTEC PVC profile machining centers combine cutting, drilling, milling, and marking processes for PVC and aluminum profiles within a single automated system. Models like SMC 360 and MCALS 650 operate with 0.1° precision, enhancing production speed and minimizing material waste. They are used in the manufacturing of windows, doors, and façade systems.

What are the advantages of an aluminum cutting machine?

SCHTEC aluminum cutting machines offer 0.1° precision with CNC-controlled servo motors. Energy-efficient motors, centralized lubrication, and a 15” touchscreen HMI ensure low maintenance and high productivity. Models like SMC 320 and SVMC 120 reduce production time by up to 20% and are used in over 65 countries.

Which profiles are compatible with CNC profile machining machines?

SCHTEC machines are compatible with all standard PVC and aluminum profiles. Models like SMC 310 and MCALS 650 can process profiles up to 6.5–7 meters in length. With automatic loading and multi-axis control, they provide fast changeovers and precise operations for different profile types.

How is the SCHTEC profile machining center installed?

SCHTEC provides on-site installation and operator training after delivery. Our 7-person service team, based in a 9,000 m² facility, offers remote service for Industry 4.0-compliant machines. We guarantee uninterrupted production with 24/7 technical support.