SVMC 120 Profile Machining & V-Type Cutting Center

SCHTEC SVMC 120: 4-axis CNC for PVC & aluminum profiles up to 6.5m. V-type cutting, 11-tool routing, 0.1° saw precision. Elevator loading, 15” touchscreen, Industry 4.0-ready.

SVMC 120 Technical Specifications

| Voltage | 400 V, 3 Ph, 50-60 Hz |

| Power Consumption | 9.8 kW, 32 A (Max Consumption) |

| Max. Profile Height | 92 mm |

| Min. Profile Height | 40 mm |

| Max. Profile Width | 125 mm |

| Min. Profile Width | 35 mm |

| Min. Cutting Depth (V) | 15 mm |

| Max. Profile Bar Length | 6,500 mm |

| Max. Process Length for Profile | 6,000 mm |

| Maximum Cutting Length | 3,500 mm (can be increased if needed) |

| Minimum Cutting Length | 320 mm |

| Min. Process Length for Profile | 600 mm |

| Short Scrap Length (Rear Waste Basket) | 275 mm |

| Scrap Length (Frontal Waste Basket) | > 400 mm |

| Shortest Cutting Length Discharged on Unloading | > 320 mm (*) |

| Longest Cutting Length Discharged on Loading | > 4,000 mm (*) |

| Tool Count | 11 high-speed air-cooled spindles |

| Saw Diameter (Top - Main Saw) | Ø500 mm, Ø30 mm bore |

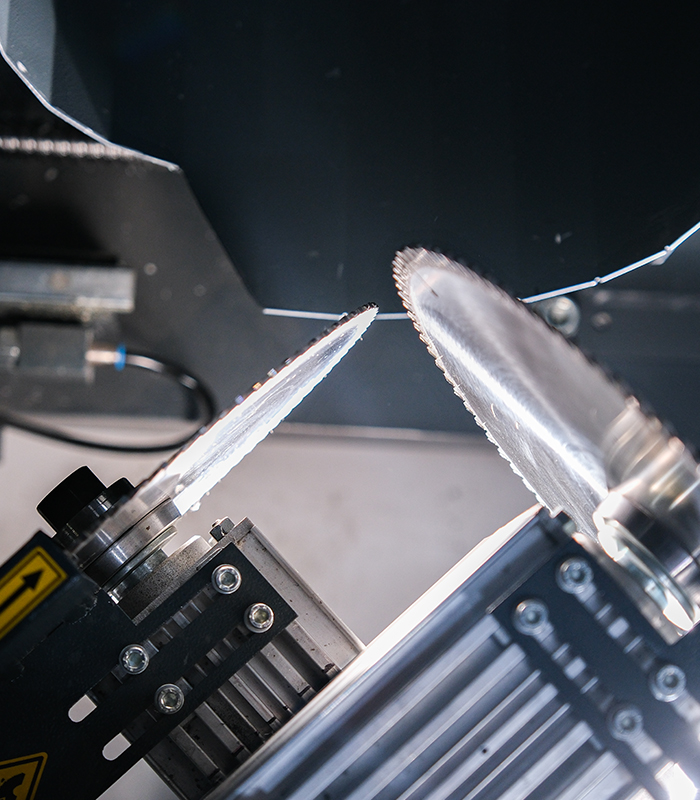

| Saw Diameter (V Notch - x2) | Ø300 mm, Ø30 mm bore |

| Max Tool RPM | 18,000 rpm |

| Max. Axes Speed (Processing) | 50 m/min |

| Max. Axes Speed (Saw) | 100 °/sec |

| Max. Axes Speed (Carrier) | 40 m/min |

| Air Pressure | 6-7 bar |

| Air Consumption | 1,480 l/min |

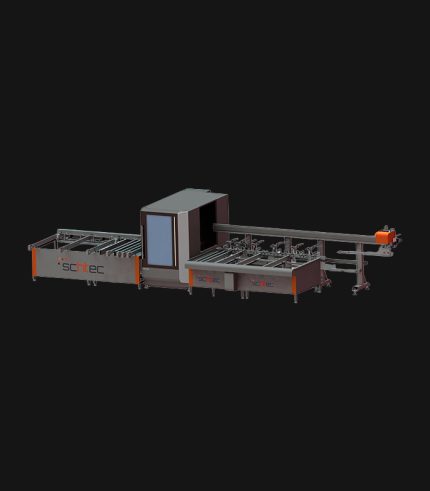

| Machine Height | 2,200 mm |

| Machine Width | 3,450 mm |

| Machine Length | 16,800 mm |

| Machine Weight | 5,350 kg |

SVMC 120 Profile Machining and V-Type Cutting Center

Standard Features

• The infeed magazine can load up to 11 profiles, with a maximum length of 6.5 meters.

• Simultaneous optimization on the machine allows it to self-optimize leftover profiles, switchable between FDS control and machine control.

• Height and width detection ensures that the correct profile is loaded.

• The newly designed loading station enables simultaneous profile loading, increasing the efficiency of profile changeovers.

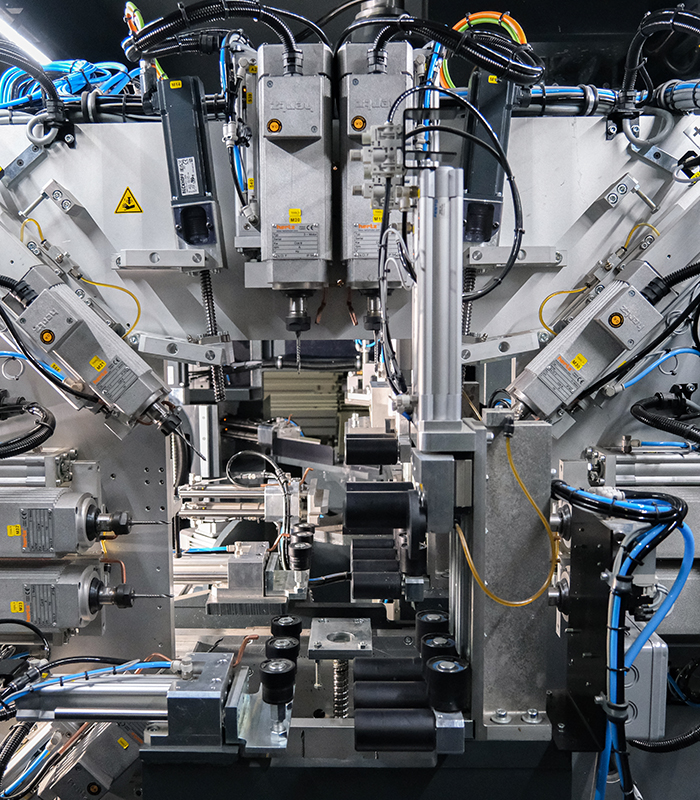

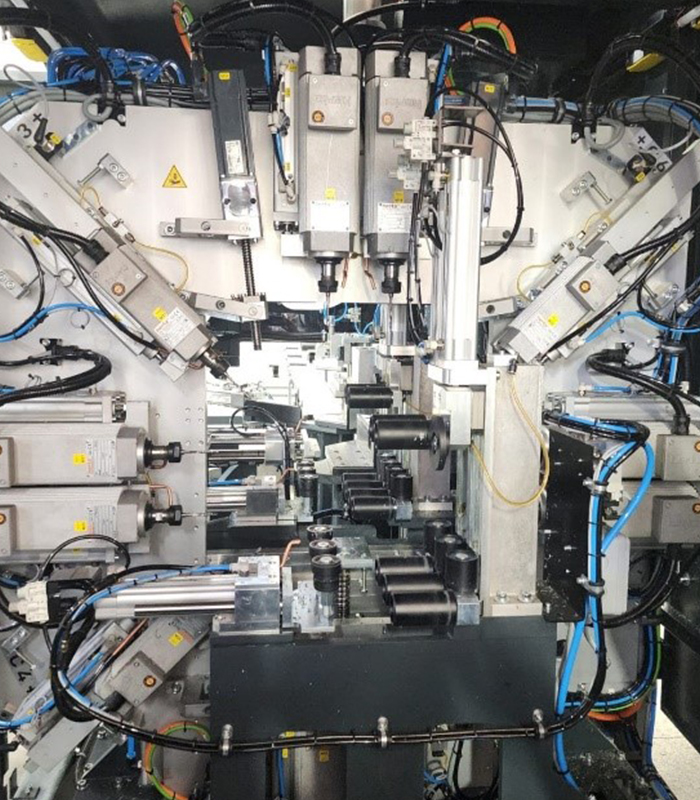

• The 4-axis routing portal includes 11 high-speed routing motors using 5mm and 8mm cutters at 0°, 90°, 180°, and 270°, plus three servo-driven angle routers with 5mm cutters for various profile suites with different drainage angles.

• This setup allows the SVMC 120 to complete all preparations on PVC profiles, such as drainage, spot marking, euro-cylinder holes, night vents, hinge holes, handle holes, and euro groove routing.

• Highly efficient simultaneous routing operations on the 4-axis portal allow machining from both the top and bottom for components like door handles and night vents.

• The servo-axis-controlled 500 mm diameter saw cuts all angles between 30° and 150° with 0.1° accuracy.

• A newly designed double clamping system stabilizes both the bevel and rebate using individual clamps and software-controlled variable clamping pressures for each of the four sawing clamps.

• Software-controlled transom support is provided for Z and T profiles.

• Private HMI software developed by the SCHTEC Software Department supports uploading data files from various window design programs and is fully compatible with UK software such as BM and First Degree.

• All alarms and machine faults are displayed on the HMI with corresponding solutions.

• The system features a 15” touchscreen and a high-performance industrial PC with a Windows Embedded operating system.

• An industrial PC-based servo control system is powered by Beckhoff technology.

• Online diagnostics and troubleshooting are available through a user-friendly interface.

• File transfer is possible via USB, Ethernet, and remote desktop over Wi-Fi or Ethernet.

• A central lubrication system reduces maintenance time.

• A scrap conveyor beneath the saw and extraction ports on all saw blade cowls improve waste management.

• The machine has a production capacity of 100–110 frames per 8-hour shift, depending on complexity, averaging approximately one piece every 18.6 seconds.

The SCHTEC SVMC 120 is a 4-axis servo-controlled center that combines V-type cutting, drilling, and milling of PVC and aluminum profiles in one system. It processes profiles up to 6.5 meters with an elevator loading system for continuous operation. V-type cutting technology ensures strong and aesthetic joints, while a multi-tool changer speeds up operations. The 15” touchscreen, user-friendly software, and Industry 4.0-compatible Ethernet connectivity make the SVMC 120 an ideal solution for high-precision and efficient production.

PVC & Aluminium Profile Machining and Cutting Center

SCHTEC SMC 360, MCCALL'S 650, SVMC 120: CNC for PVC & aluminum, 0.1° precision, 6.5m capacity. Automate window & door production. Get a quote!

FAQ

What is a PVC profile machining center and what is it used for?

SCHTEC PVC profile machining centers combine cutting, drilling, milling, and marking processes for PVC and aluminum profiles within a single automated system. Models like SMC 360 and MCALS 650 operate with 0.1° precision, enhancing production speed and minimizing material waste. They are used in the manufacturing of windows, doors, and façade systems.

What are the advantages of an aluminum cutting machine?

SCHTEC aluminum cutting machines offer 0.1° precision with CNC-controlled servo motors. Energy-efficient motors, centralized lubrication, and a 15” touchscreen HMI ensure low maintenance and high productivity. Models like SMC 320 and SVMC 120 reduce production time by up to 20% and are used in over 65 countries.

Which profiles are compatible with CNC profile machining machines?

SCHTEC machines are compatible with all standard PVC and aluminum profiles. Models like SMC 310 and MCALS 650 can process profiles up to 6.5–7 meters in length. With automatic loading and multi-axis control, they provide fast changeovers and precise operations for different profile types.

How is the SCHTEC profile machining center installed?

SCHTEC provides on-site installation and operator training after delivery. Our 7-person service team, based in a 9,000 m² facility, offers remote service for Industry 4.0-compliant machines. We guarantee uninterrupted production with 24/7 technical support.