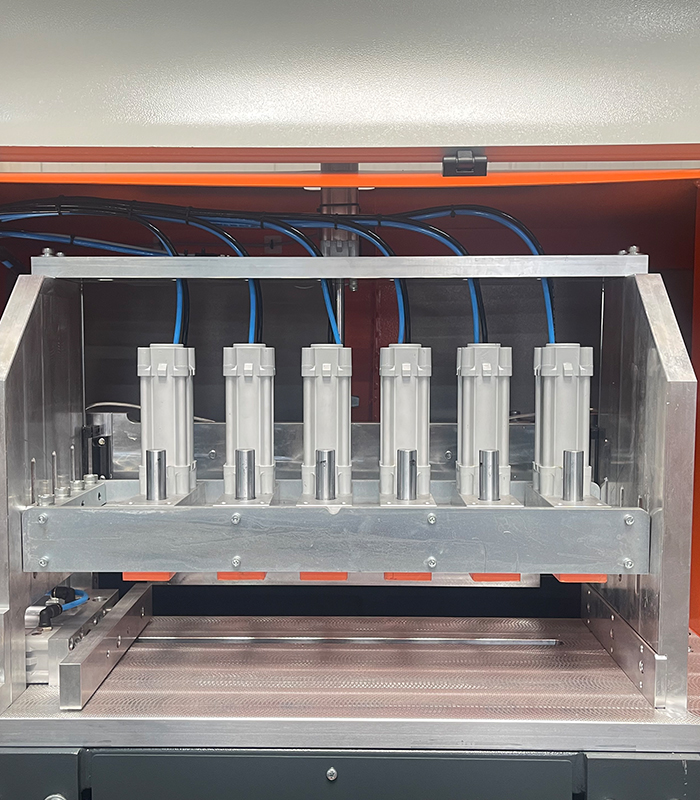

MT 256 Automatic Multiple End Milling Machine

The SCHTEC MT 256 offers precise, sensor-assisted milling for 1-6 PVC mullion profiles at once.

MT 256 Technical Specifications

| Power Supply | 400 V, 3 Ph, 50-60 Hz |

| Total Power | 1.65 kW (1.1 kW + 0.55 kW) |

| Air Pressure | 6-8 bar |

| Air Consumption | 60 l/min |

| Max. Profile Width | 120 mm |

| Max. Profile Height | 90 mm |

| Max. Knife Diameter | 130 mm |

| Max. End Milling Height | 90 mm |

| Max. End Milling Depth | 30 mm |

| Machine Height | 1,640 mm |

| Machine Length | 1,600 mm |

| Machine Width | 700 mm (1,460 mm with support table) |

| Machine Weight | 350 kg |

MT 256 Multiple End Milling Machine

Standard Features

- End milling of the PVC and Aluminium transom profiles with high quality and precision

- Easy speed adjustment for knifes

- Easy stop point adjustment for end milling by rotary revolver system

- Very high safety protect by upper side cover

- Anti-Fracture protection on profile by speed adjustment during end milling process

- Easy knife change system by plug&play knife changer

- Machine adjust axis way according to profile count automatically

- Onboard toolbox and safe box for spare knifes

- High quality and precision on end milling process by double clamper on side clamp system

- This system also ensure sliding of profiles and against to miter joint problems

- Support arms provide up to 2,5 mt profiles for end milling

- Machine can work between 1 to 6 profile counts.

The SCHTEC MT 256 is an automatic, sensor-assisted machine capable of precisely milling 1 to 6 PVC mullion profiles simultaneously. Its anti-slip system, pneumatic blade change, and 2.5-meter support stand ensure efficient and error-free operation. With a 1.65 kW motor, it fits well into compact production spaces. It is an ideal solution for sliding profiles.

PVC End Milling Machines

SCHTEC's PVC End Milling Machines deliver 0.1mm precision for window & door profiles. Models MT 250 & MT 256 ensure 30% faster production. Ideal for small workshops to large factories. Get a quote!

FAQ

What is a mullion end milling machine and what is it used for?

SCHTEC mullion end milling machines mill the ends of PVC and aluminum profiles, creating smooth, solid, and aesthetically pleasing joints. Models MT 250 and MT 256 feature automatic positioning and pneumatic clamping to minimize operator errors. These machines enhance assembly quality and reduce material waste in window and door production.

What are the advantages of milling PVC profiles?

Milling PVC profiles smooths the joining surfaces, making assembly easier and improving the visual finish. SCHTEC machines operate with millimeter-level precision, offer 20% energy savings, and support multiple profile types for flexibility. The MT 256 can process up to 6 profiles simultaneously, speeding up production.

Which profiles are compatible with aluminum frame machines?

SCHTEC mullion end milling machines are compatible with all standard PVC and aluminum profiles. The MT 250 features a dual-blade system that requires no adjustments, while the high-capacity MT 256 handles various profile sizes and types with precision and quick changeover.

How is the SCHTEC mullion milling machine installed?

SCHTEC provides on-site installation and operator training after delivery. Supported by our 7-person service team from a 9,000 m² facility, the machines feature centralized lubrication and sensor-assisted systems for low maintenance. With 24/7 technical support, SCHTEC ensures uninterrupted production.