CM 610: High-Precision CNC Corner Cleaning Machine

Schtec CM 610 CNC: High-precision corner cleaning for medium-scale PVC lines. 2-axis servo, auto measure & DXF. Cleans 320-360 frames/shift.

CM 610 Technical Specifications

| Voltage | 400 V AC, 3 P, 50/60 Hz |

| Power Consumption | 7 kW, 18 A |

| Air Pressure | 6–8 bar |

| Air Consumption | 110 lt./min |

| Saw Blade Details | Ø 250 x Ø 30 x 3.2 mm, Z=80 |

| Saw Blade rpm | 5,200 rpm |

| Drillers rpm | 14,000 rpm |

| Max. Axes Speed | 25 m/min |

| Max. Outer Frame Dimension | Limitless |

| Max. Profile Height | 140 mm |

| Min. Profile Height | 35 mm |

| Max. Profile Width | 120 mm |

| Machine Height | 1,900 mm |

| Machine Length | 2,560 mm |

| Machine Width | 900 mm |

| Machine Weight | 600 kg |

| Tool Count | 11 pieces |

| Capacity | 320–360 frames / 8 hours (based on one corner cleaning) |

| Size | UK | US | EU | Japan |

| XS | 6 - 8 | 4 | 34 | 7 |

| S | 8 -10 | 6 | 36 | 9 |

| M | 10 - 12 | 8 | 38 | 11 |

| L | 12 - 14 | 10 | 40 | 13 |

| XL | 14 - 16 | 12 | 42 | 15 |

| XXL | 16 - 28 | 14 | 44 | 17 |

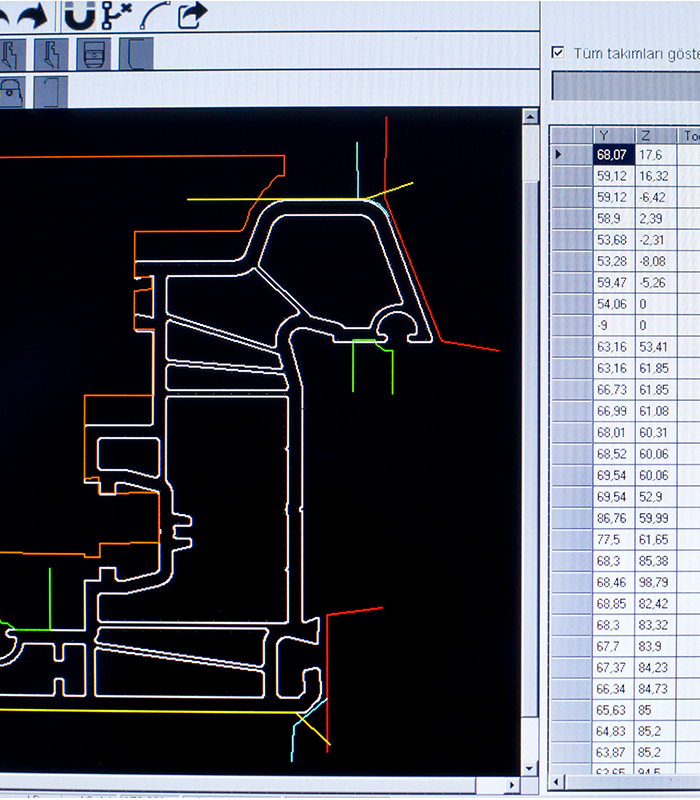

CM 610 CNC Corner Cleaning Machine

Standard Features

- Corner cleaning stability with 2 axes high-speed servo controlled axes

- Automatic knife selection for selected profile foil type (colour / white)

- High quality corner cleaning result through durable special knife and bit designs

- Faultless cleaning of surface burrs with automatic measurement system

- File transfer by USB

- Easy programming support via DXF,DWG or PDF file extensions

- Central lubrication system for all bearings, axes and sliding bearings

- 10” TouchScreen

- All alarm sand messages can shown on the machine interface by way of software which developed by SCHTEC Software R&D Department.

The Schtec CM 610 is a compact CNC machine offering high-precision corner cleaning. With a 2-axis servo system and a capacity of 320–360 frames per 8-hour shift, it is ideal for medium-scale production lines. It features compatible blades for colored and white PVC profiles, an automatic measurement system, and DXF/DWG programming support for accurate and efficient burr removal. USB file transfer, a 10” touchscreen, and a centralized lubrication system make it easy to operate.

PVC Corner Cleaning Machines

Discover SCHTEC's CNC and manual corner cleaning machines for PVC window and door profiles. High-speed, high-precision options like CM 620 and CC 254. Get a quote today!

FAQ

What is a corner cleaning machine and what is it used for?

SCHTEC corner cleaning machines remove burrs formed after welding in PVC window and door production, ensuring smooth corners. This enhances aesthetics, gasket compatibility, and assembly quality. Manual models are ideal for small workshops, while CNC-controlled machines like the CM 620 deliver high efficiency in large-scale production lines.

What are the advantages of PVC window corner cleaning machines?

SCHTEC corner cleaning machines offer a capacity of over 400 frames per 8-hour shift. Special blade systems for colored and white profiles, DXF/DWG-supported programming, and centralized lubrication provide 20% energy savings. Used in over 65 countries, they boost production with remote service support.

Which profiles are compatible with CNC corner cleaning machines?

SCHTEC machines are compatible with all standard PVC and aluminum profiles. They include special blade systems for white, colored, and laminated profiles. The CM 620 uses servo axes for automatic measurements, ensuring precise and fast cleaning across different profile types.

How is a SCHTEC corner cleaning machine installed?

SCHTEC provides on-site installation and operator training after delivery. Our 7-person service team from the 9,000 m² facility offers 24/7 technical support via remote connection. A centralized lubrication system reduces maintenance needs, ensuring continuous production.