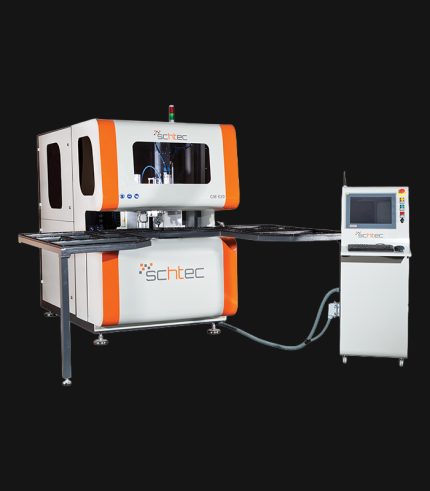

CC 254: 4 Cutters Corner Cleaning Machine

Schtec CC 254: Economical manual 4-cutter PVC corner cleaner for precise burr removal. Auto centering ensures safety. Ideal for small/medium lines.

CC 254 Technical Specifications

| Voltage | 400 V AC, 3 P, 50/60 Hz |

| Total Power | 1.1 kW |

| Spindle Speed | 3,000 rpm |

| Air Pressure | 6–8 bar |

| Air Consumption | 95 lt./min |

| Max. Knife Diameter | 160 mm |

| Max. Profile Width | 120 mm |

| Max. Profile Height | 90 mm |

| Min. Profile Height | 40 mm |

| Machine Height | 1,700 mm |

| Machine Length | 1,360 mm (With Support Table: 2,170 mm) |

| Machine Width | 960 mm (With Support Table: 2,140 mm) |

| Machine Weight | 360 kg |

CC 254 Corner Cleaning Machine (4 Cutters)

Standard Features

- High quality corner cleaning result through durable special knifes on foiled or white welded profiles for bottom and upper surfaces

- High quality corner cleaning result through 4 different type of end milling tools on outside of the welded profiles

- Corner cleaning stability with automatic centering system for welded frames

- High precision on profile stabilization with vertical clamps

- Support arm is standard equipment

The Schtec CC 254 is a powerful and economical machine designed for manual removal of welding burrs in PVC window and door production. It uses surface scraping blades for top and bottom surfaces and four different notching blades for precise cleaning of outer corners. With automatic centering, vertical clamping pistons, and a standard frame support table, operations are performed safely. With a 1.1 kW motor and up to 120 mm profile width capacity, it is ideal for small and medium-scale production lines.

PVC Corner Cleaning Machines

Discover SCHTEC's CNC and manual corner cleaning machines for PVC window and door profiles. High-speed, high-precision options like CM 620 and CC 254. Get a quote today!

FAQ

What is a corner cleaning machine and what is it used for?

SCHTEC corner cleaning machines remove burrs formed after welding in PVC window and door production, ensuring smooth corners. This enhances aesthetics, gasket compatibility, and assembly quality. Manual models are ideal for small workshops, while CNC-controlled machines like the CM 620 deliver high efficiency in large-scale production lines.

What are the advantages of PVC window corner cleaning machines?

SCHTEC corner cleaning machines offer a capacity of over 400 frames per 8-hour shift. Special blade systems for colored and white profiles, DXF/DWG-supported programming, and centralized lubrication provide 20% energy savings. Used in over 65 countries, they boost production with remote service support.

Which profiles are compatible with CNC corner cleaning machines?

SCHTEC machines are compatible with all standard PVC and aluminum profiles. They include special blade systems for white, colored, and laminated profiles. The CM 620 uses servo axes for automatic measurements, ensuring precise and fast cleaning across different profile types.

How is a SCHTEC corner cleaning machine installed?

SCHTEC provides on-site installation and operator training after delivery. Our 7-person service team from the 9,000 m² facility offers 24/7 technical support via remote connection. A centralized lubrication system reduces maintenance needs, ensuring continuous production.