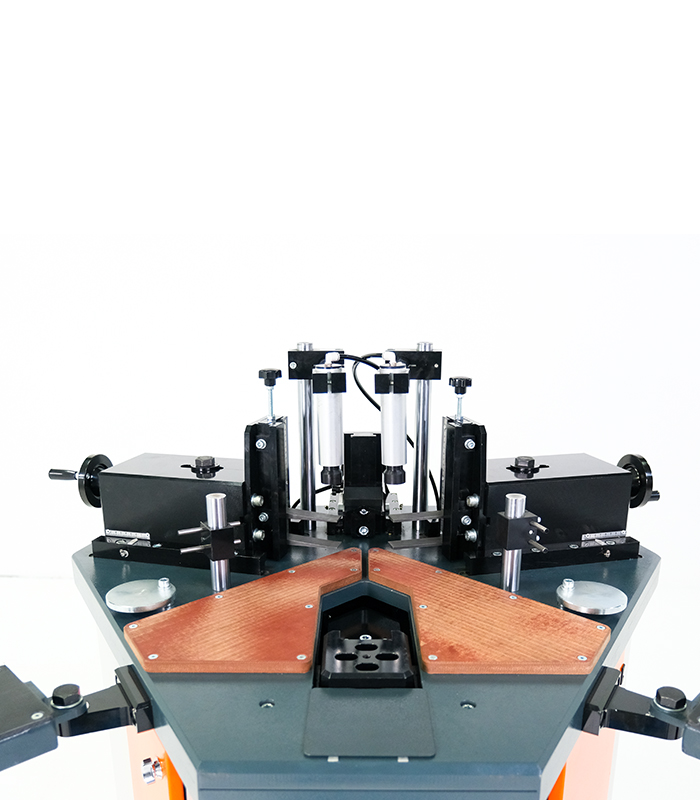

CP 290 Corner Crimping Machine

SCHTEC CP 290: Precise 90° aluminum joints with 7-ton/cm² force. Quick blade change, foot pedal control, and front mitre system ensure efficiency for profiles up to 220 mm.

Technical Specifications

| Power Supply | 220 V, 1 Ph, 50-60 Hz |

| Power Output | 2.2 kW, 5.5 A |

| Side Cylinder Pressing Power | 7 ton/cm² |

| Upper Cylinder Pressing Power | 3 ton/cm² |

| Air Pressure | 6-8 bar |

| Air Consumption | 60 l/min |

| Max. Profile Height | 220 mm |

| Max. Knives Pressing Height | 190 mm |

| Min. Frame Size | 350 mm x 350 mm |

| Machine Height | 1,300 mm |

| Machine Length | 900 mm (1,760 mm with support arms) |

| Machine Width | 1,200 mm (2,525 mm with support arms) |

| Machine Weight | 575 kg |

CP 290 Corner Crimping Machine

Standard Features

- Joins Aluminium profiles corners by pressing them together

- Hidropneumatic high pressure power system (easy maintenance)

- Ability to work with different profiles sizes

- Small frames can be joined by specially designed clamping unit

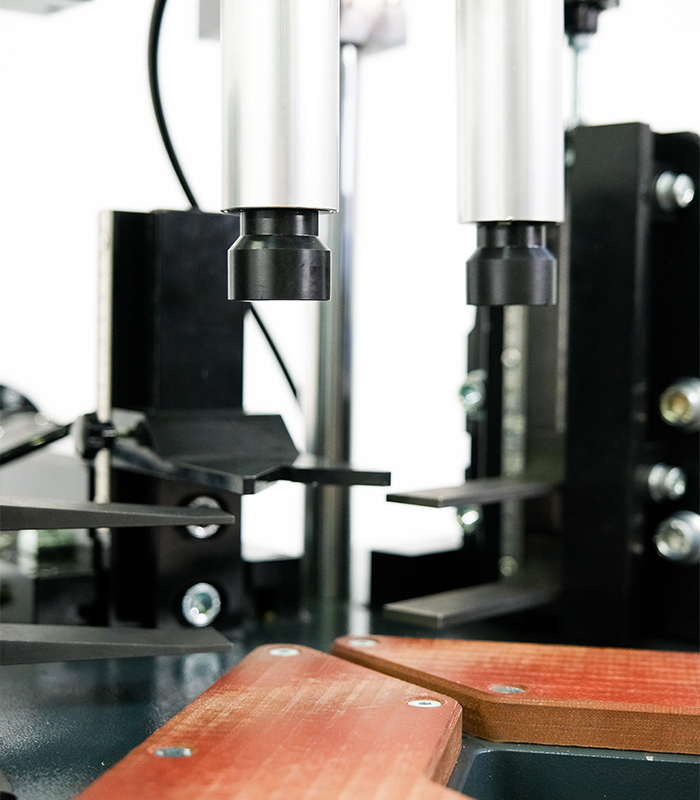

- Quick blade changing system

- The front set square system is designed for easy profile loading and unloading

- Pressing process is done step by step with a foot pedal

- Support arms are included as standard

The Schtec CP 290 is a high-pressure corner crimping machine designed to provide strong and aesthetically pleasing 90° joints for aluminum profiles. With a hydropneumatic system delivering 7 tons/cm² of pressing force, the CP 290 ensures maximum durability and precision, especially for large profiles.

The machine features quick blade change and a special clamping unit for flexible and safe operation. Step-by-step control is provided via a foot pedal, while the front mitre system speeds up profile alignment and positioning. Supporting profile heights up to 220 mm, with a weight of 575 kg, robust support arms, and ergonomic design, the CP 290 enables smooth operation across various frame sizes.

Aluminium Corner Crimping Machines

SCHTEC CP 290 Aluminium Corner Crimping Machine: 7 ton/cm² pressure, 220 mm profile height, and hydropneumatic system. Save 30% time with quick blade change. Ideal for windows/doors. Get a quote!

FAQ

What is a corner crimping machine and what is it used for?

SCHTEC corner crimping machines are designed to join 90° corners of PVC and aluminum window/door frames in a strong and aesthetically pleasing way. The CP 290 model delivers high performance with 7 tons/cm² of hydropneumatic press force. It supports profiles up to 220 mm and allows quick blade changes, ensuring flawless joints across various frame sizes.

What are the advantages of a PVC window corner joining machine?

SCHTEC corner crimping machines operate quietly and with low maintenance costs, thanks to the 7 tons/cm² press force and hydropneumatic system. Their user-friendly design, fast blade change system, and support arms enable flexible production. The CP 290, used in over 65 countries, increases production efficiency by 15%.

Which profiles are compatible with aluminum profile crimping machines?

SCHTEC corner crimping machines are compatible with all standard PVC and aluminum profiles. The CP 290 supports profiles up to 220 mm in height and offers special support arms for small frames, making it suitable for all frame sizes.

How is the SCHTEC corner crimping machine installed?

SCHTEC provides on-site installation and operator training after delivery. Backed by a 7-person service team from our 9,000 m² facility, we offer 24/7 technical support. The hydropneumatic system and user-friendly design minimize maintenance needs and ensure uninterrupted production.