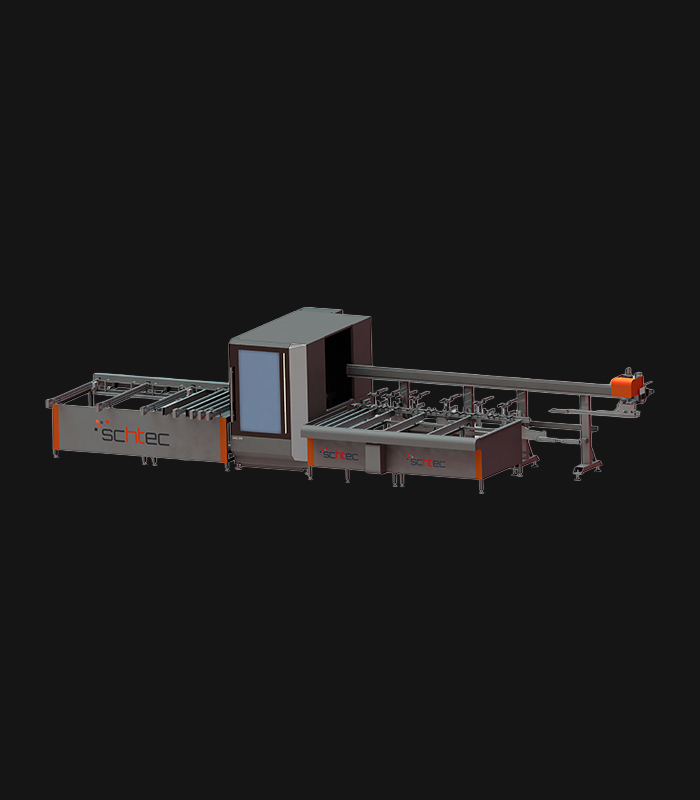

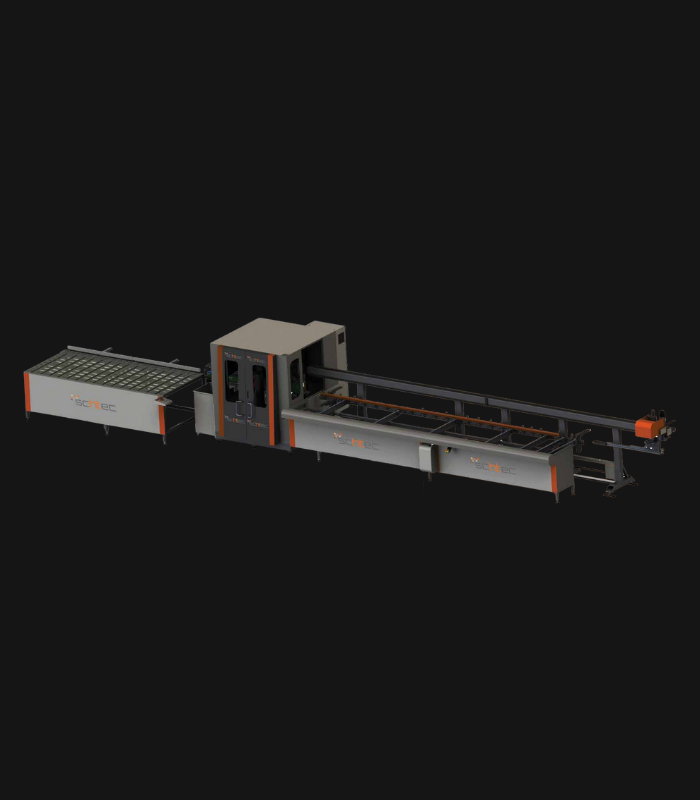

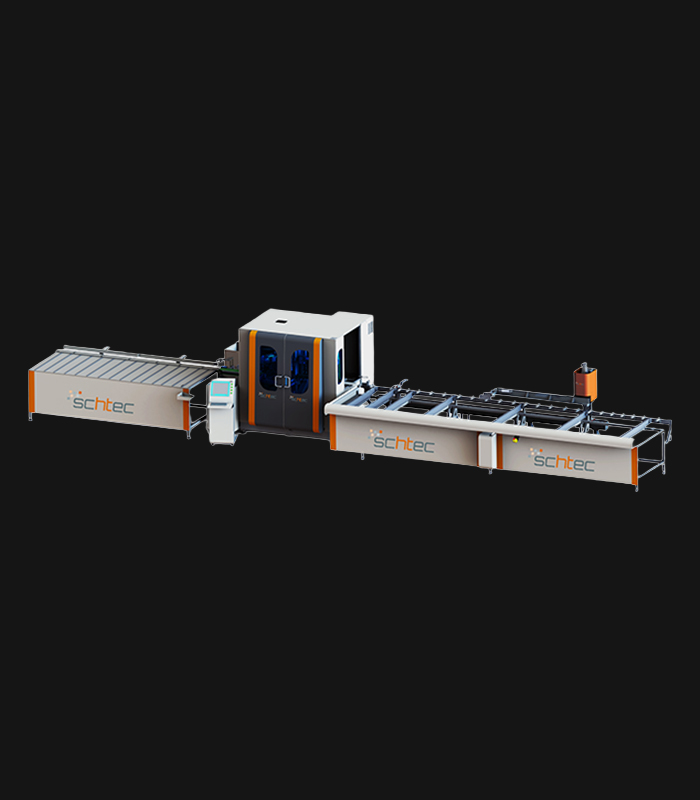

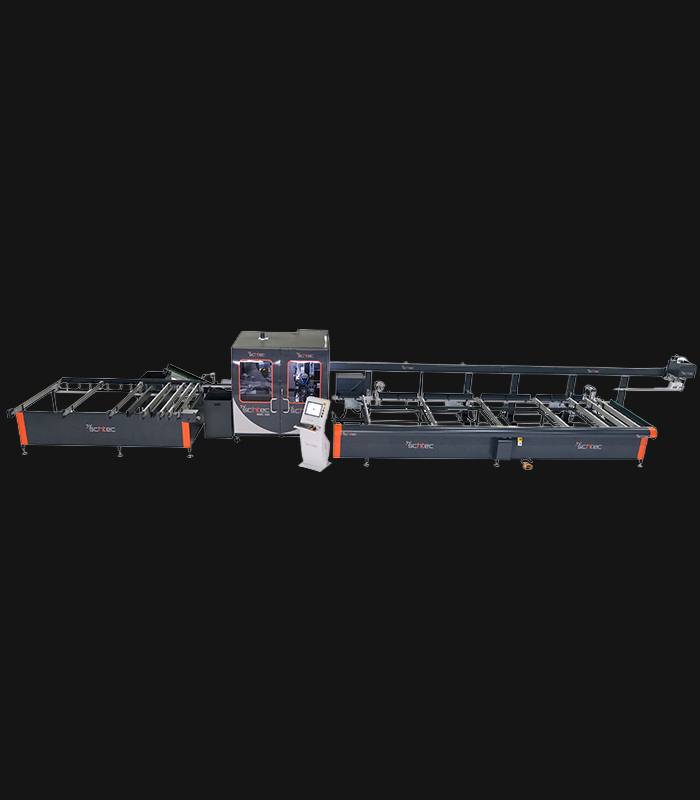

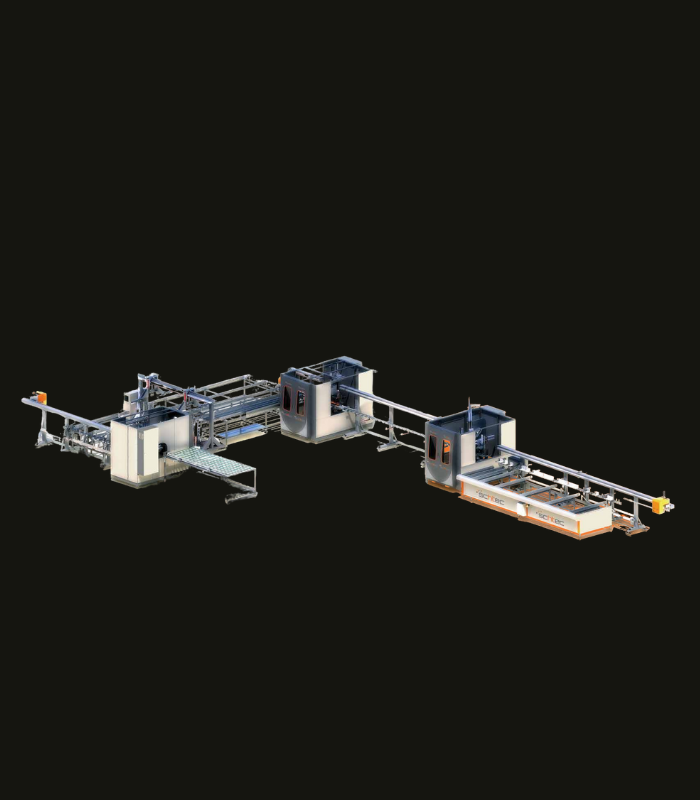

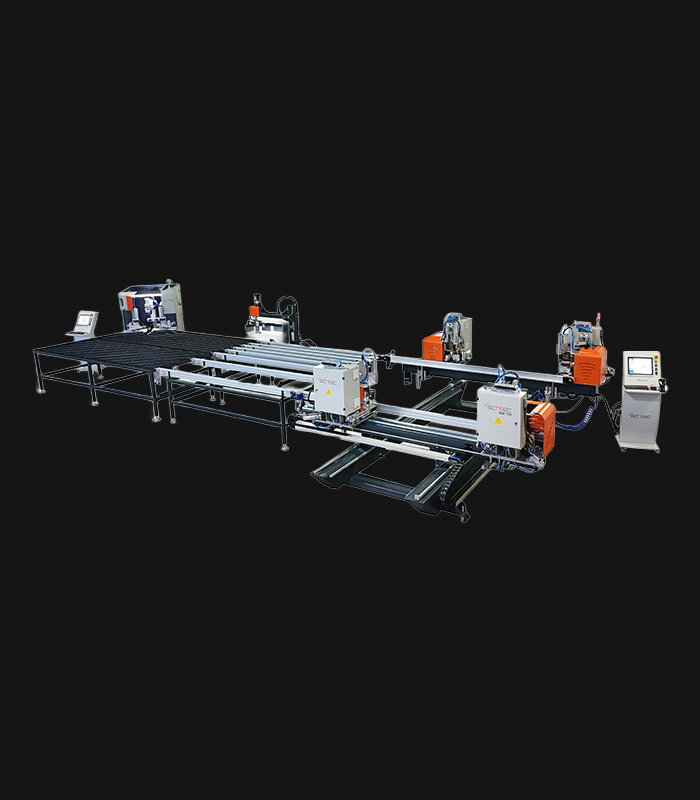

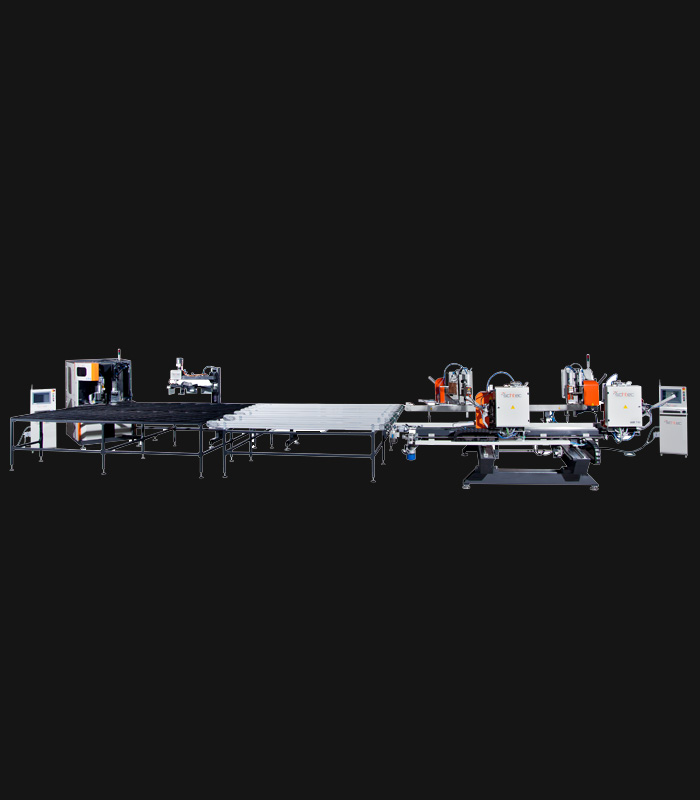

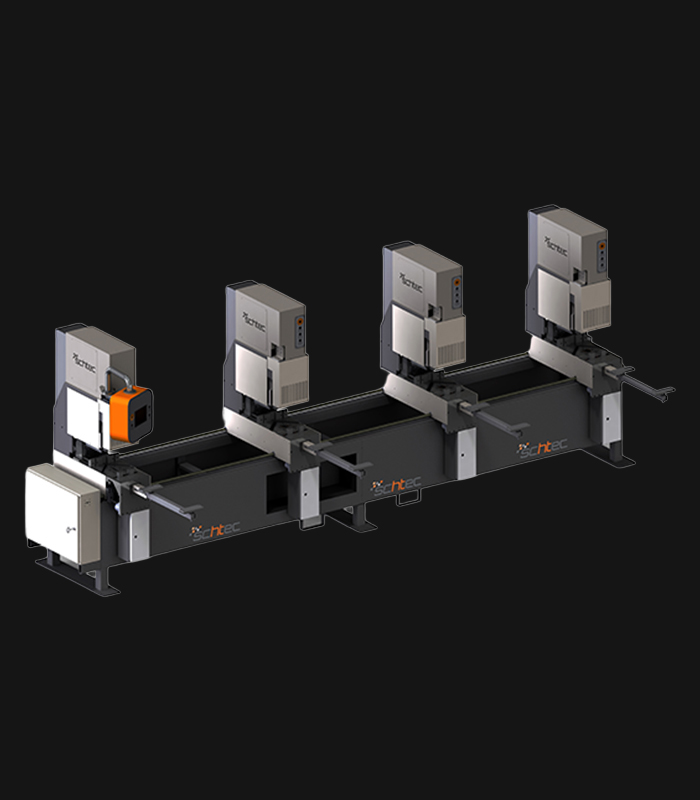

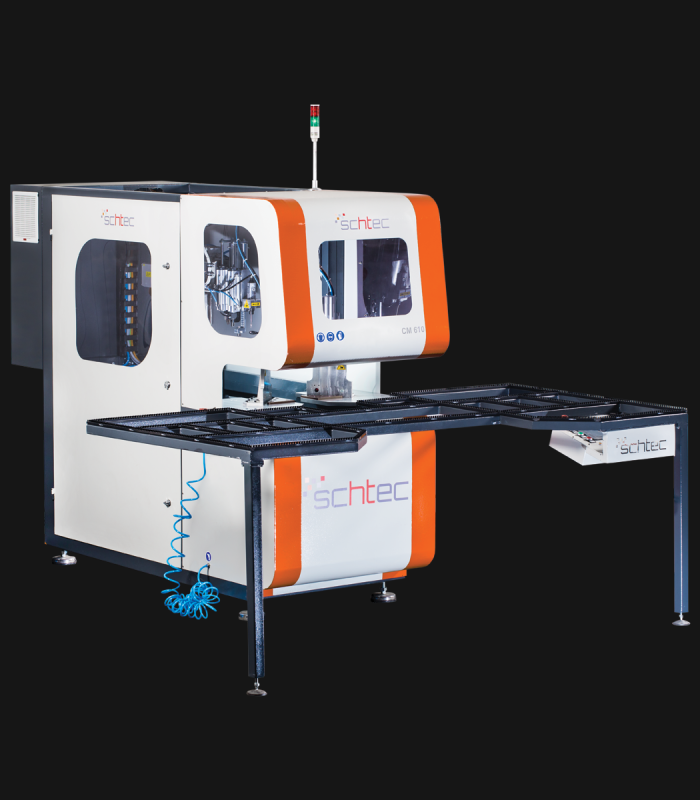

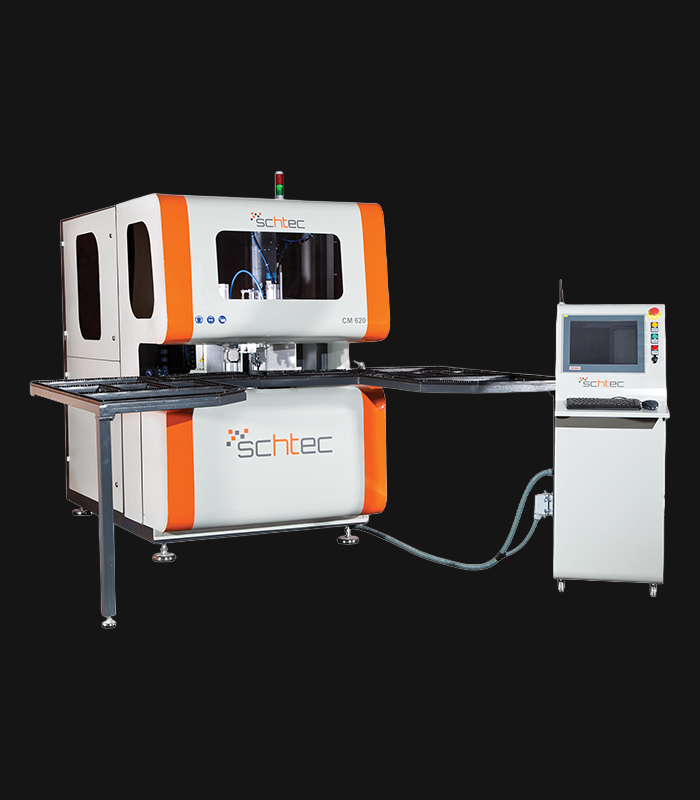

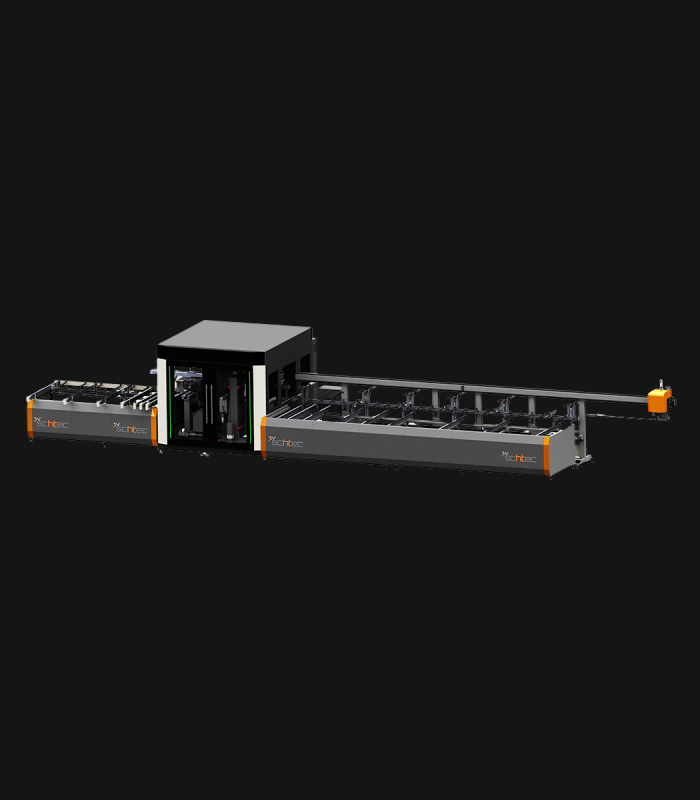

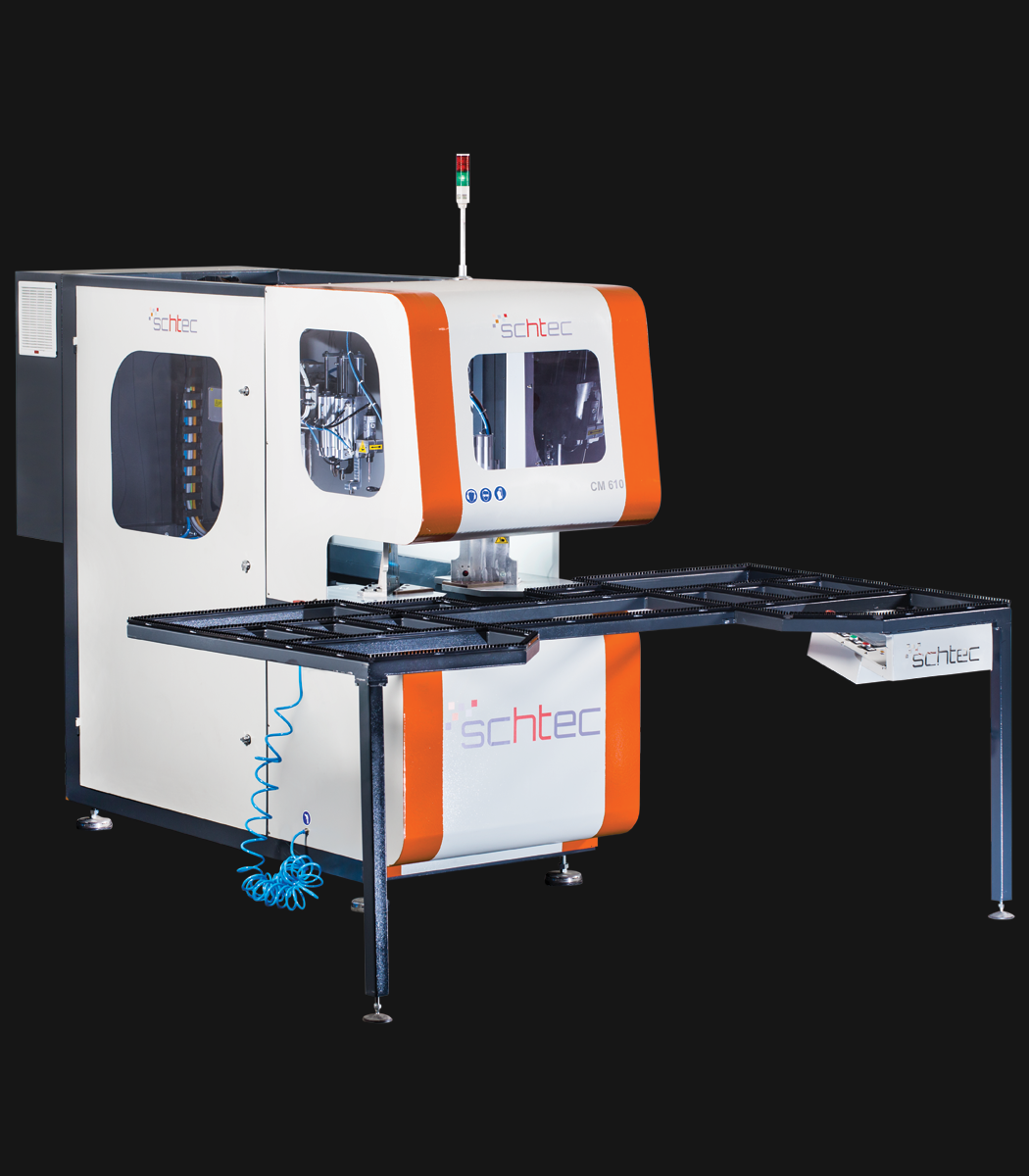

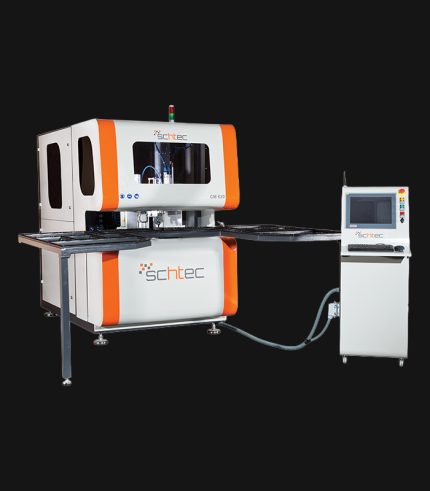

CM 610 CNC Corner Cleaning Machine

Schtec CM 610 CNC: High-precision corner cleaning for medium-scale PVC lines. two-axis servo, auto measure & DXF. Cleans 320-360 frames/ 8 hours.

CM 610 Technical Specifications

| Voltage | 400V, 3 PH, 50-60 HZ |

| Power Consumption | 3.45 kW, 15 A |

| Air Pressure | 6–8 bar |

| Air Consumption | 110 lt./min |

| Saw Blade Details | Ø 250 x Ø 30 x 3.2 mm, Z=80 |

| Saw Blade rpm | 5,200 rpm |

| Drillers rpm | 14,000 rpm |

| Max. Axes Speed | 25 m/min |

| Max. Outer Frame Dimension | Limitless |

| Max. Profile Height | 140 mm |

| Min. Profile Height | 35 mm |

| Max. Profile Width | 120 mm |

| Machine Height | 1,900 mm |

| Machine Length | 2,560 mm |

| Machine Width | 900 mm |

| Machine Weight | 600 kg |

| Tool Count | 11 pieces |

| Capacity | 320–360 frames / 8 hours (based on one corner cleaning) |

SKU:

CM-610

Category: Corner Cleaning Machines

Description

Standard Features

- Corner cleaning stability with two axes high-speed servo controlled axes

- Automatic knife selection for selected profile foil type (colour / white)

- High quality corner cleaning result through durable special knife and bit designs

- Faultless cleaning of surface burrs with automatic measurement system

- File transfer by USB

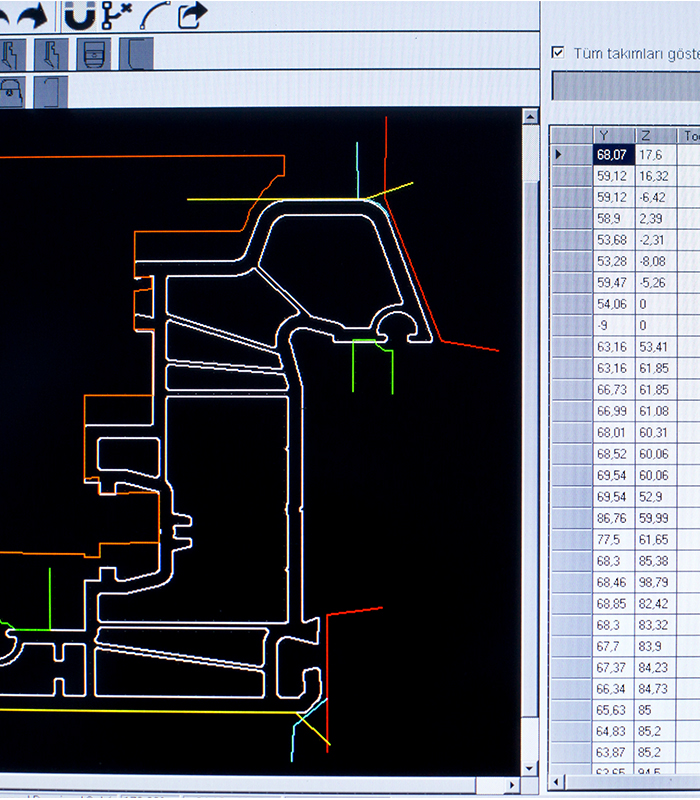

- Easy programming support via DXF,DWG or PDF file extensions

- Central lubrication system

- 10” TouchScreen

- All alarm sand messages can shown on the machine interface by way of software which developed by SCHTEC Software R&D Department.

Product Description

The Schtec CM 610 is a compact CNC machine offering high-precision corner cleaning. With a two-axis servo system and a capacity of 320–360 frames per 8-hour shift, it is ideal for medium-scale production lines. It features compatible blades for colored and white PVC profiles, an automatic measurement system, and DXF/DWG programming support for accurate and efficient burr removal. USB file transfer, a 10” touchscreen, and a centralized lubrication system make it easy to operate.

FAQ

Corner Cleaning Machines

Frequently Asked Questions

Find quick answers to common questions about our Corner Cleaning Machines.

1. What is the purpose of a corner cleaning machine in PVC profile production?

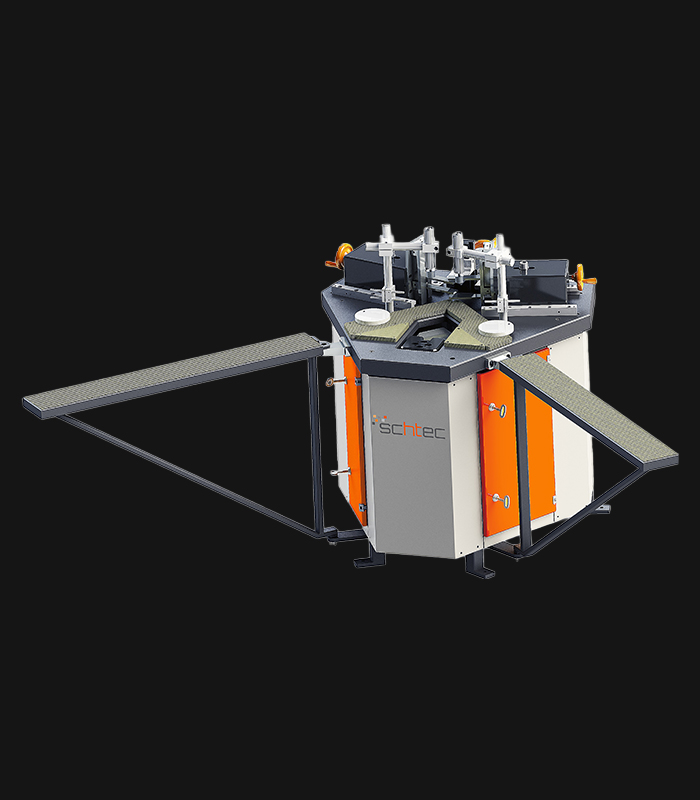

A corner cleaning machine removes the excess welding flash, burrs, and material residues from the welded 90° corners of PVC frames, delivering clean and precise edges. It ensures that frames are ready for sealing, glazing or further finish without manual rework. Proper cleaning avoids interference with gaskets, joints, and hardware, improving product aesthetics and performance. In automated lines, corner cleaning is an essential finishing step to maintain throughput and quality consistency.

2. What features are essential in a high‑performance corner cleaning machine?

Key features include servo‑driven multi‑axis control, automatic knife selection for different profile foils (colour/white), high‑precision centering and clamping systems, tool change mechanisms, and PC‑based control with remote diagnostics. A reliable lubrication system, automatic measurement of profile surfaces, and alarm system further enhance reliability. The machine should support DXF/DWG input or profile program files for flexibility. All these features work together to ensure fast, accurate, and repeatable corner cleaning.

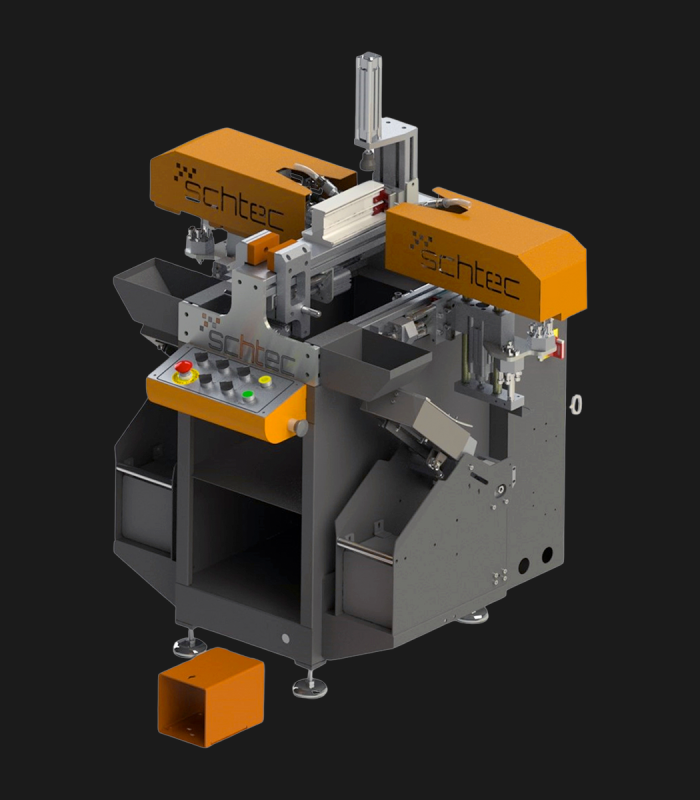

3. How does CM 620 Corner Cleaning Machine perform and which strengths does it bring?

The CM 620 offers high‑speed and high‑accuracy corner cleaning using a 2‑axis servo system. It supports automatic knife selection depending on profile foil (colour or white), improving adaptability. The control is via industrial PC, supporting DXF/DWG import, remote connection (WiFi/Network), and centralized lubrication. It also has features like automatic measurement of profile surfaces and real‑time error reporting through its HMI.

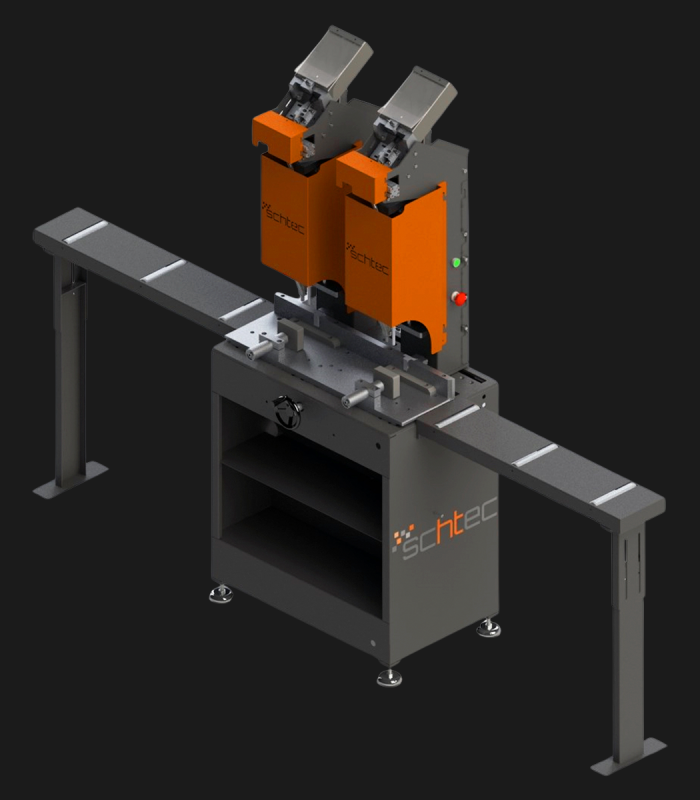

4. What are the advantages and limitations of a simpler machine like CC 254 Four Cutter Corner Cleaning Machine?

The CC 254 uses four cutters to trim weld flash and burrs from frames. It has automatic centering for welded frames, vertical clamps for profile stabilization, and durable special knives suitable for foiled or white profiles. Its simplicity leads to lower cost and easier maintenance, but it may be less flexible in handling diverse profile shapes or foil types compared to CNC models.

5. What maintenance practices help keep corner cleaning machines operating reliably?

Keep cutting knives and bits sharp and free of residue, and inspect them for wear regularly. Clean the clamping and centering systems to prevent debris accumulation that can affect accuracy. Periodically calibrate servo axes, sensors, and measurement systems to maintain precision. Verify lubrication, air supply lines, and system seals, and monitor alarms or fault logs for early signs of drift. Implement preventive maintenance schedules to reduce unplanned stops and maintain product quality.