5 Core Advantages of Automated Corner Cleaning

Deciding to integrate automation into your production line is a significant step. While the benefits are often summarized as "better quality and speed," the true impact of a PVC corner cleaning machine is far more profound and multifaceted. This article will take a deep dive into the five core advantages that this technology brings, moving beyond simple labels to explore how it directly enhances your product, your process, and your profitability.

Flawless Aesthetics and Superior Product Quality

In today's competitive market, the perceived quality of a window is paramount. The first thing a customer notices is the finish, and the corners are a critical focal point. An automated corner cleaner ensures that every corner is perfectly smooth, sharp, and free of any trace of the welding seam. It creates a seamless transition that makes the joint look as though it were molded from a single piece of PVC. This level of consistent, flawless finish is nearly impossible to replicate manually across hundreds of units. It elevates the final product from merely functional to truly premium, directly enhancing your brand's reputation for quality craftsmanship.

Significant Boost in Production Speed and Efficiency

One of the most immediate and impactful advantages of an automated corner cleaner is the dramatic increase in production speed. While a skilled worker might spend several minutes manually cleaning a single corner, an automated machine completes its entire, multi-step cycle in just a matter of seconds. This difference isn't a minor improvement; it's a transformation of your workflow. This speed eliminates what is often a major bottleneck in the window production line. Instead of welded frames piling up while waiting for manual finishing, the automated cleaner keeps pace with the welding machine, creating a smooth, continuous, and predictable flow of work. This operational efficiency translates directly into higher throughput, enabling you to manufacture significantly more windows in every shift and meet customer deadlines with confidence.

Consistency and Elimination of Human Error

Even the most skilled human operator is subject to variability due to factors like fatigue, distraction, or minor differences in technique. This means no two manually cleaned corners are ever 100% identical. A machine, however, operates on a programmed set of instructions, performing the exact same precise movements every single time. This robotic precision guarantees a level of consistency that is simply unattainable manually, ensuring the first window of the day has the exact same flawless finish as the last. This uniformity is crucial for building a brand reputation that customers trust. Furthermore, automation eliminates the risk of costly mistakes; the machine will not accidentally gouge a profile, which reduces material waste, saves on rework time, and protects your business from the reputational damage of inconsistent quality.

Reduced Material Waste and Long-Term Cost Savings

Every frame that is scrapped due to a manual cleaning error is a direct financial loss. By virtually eliminating these mistakes, an automated corner cleaner has a direct and positive impact on your material costs and overall sustainability. The savings also extend beyond materials; the "get it right the first time" consistency of a machine eliminates the need for time-consuming and expensive rework and allows you to allocate your skilled technicians to more complex, value-added tasks instead of repetitive finishing.

When you combine these operational savings with the increased revenue from higher production throughput, the financial case becomes clear. The initial capital outlay for a corner cleaning machine should not be seen as an expense, but as a strategic investment. It is designed to deliver a clear and measurable return on investment (ROI) that contributes to the long-term profitability and stability of your business.

Enhanced Corner Durability and Structural Integrity

A corner's quality extends deeper than its surface appearance; it includes its long-term structural integrity. While an aggressive manual cleaning can inadvertently weaken the welded joint by removing too much material or creating stress points, a machine's process is designed to be non-invasive. An automated cleaner is programmed for precision, removing only the excess weld seam while preserving the profile’s original wall thickness. This controlled cutting action maintains the maximum strength of the weld, contributing to the overall rigidity of the frame. The result is a more durable and reliable product, better equipped to handle the stresses of transport, installation, and daily use, ultimately leading to greater customer satisfaction and fewer warranty claims.

Conclusion

In conclusion, these five core advantages illustrate that an automated corner cleaning machine is far more than a simple upgrade. It is a strategic investment that delivers compounding returns in quality, efficiency, and profitability. By transforming a manual, variable process into a fast, precise, and reliable one, this technology provides a clear path to producing a superior product and building a stronger, more competitive business.

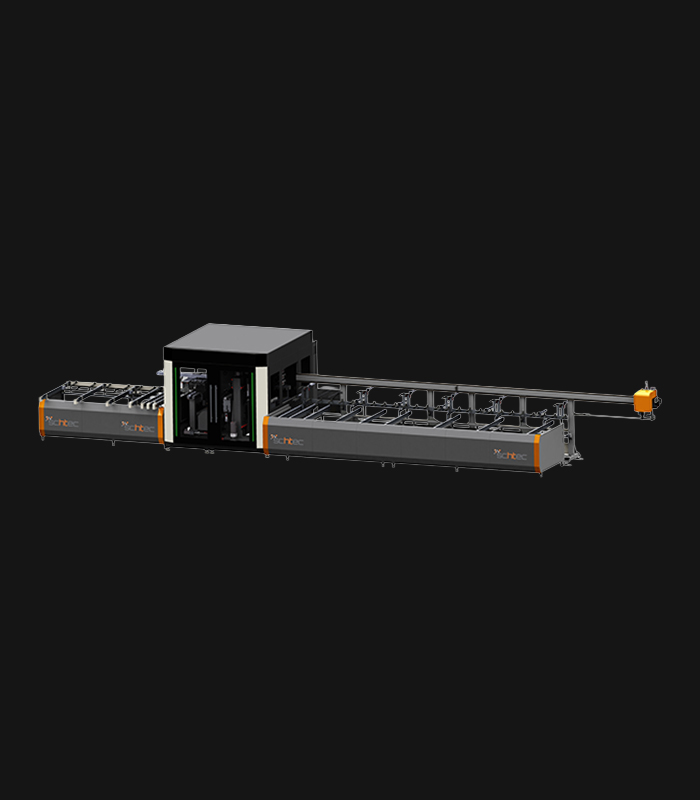

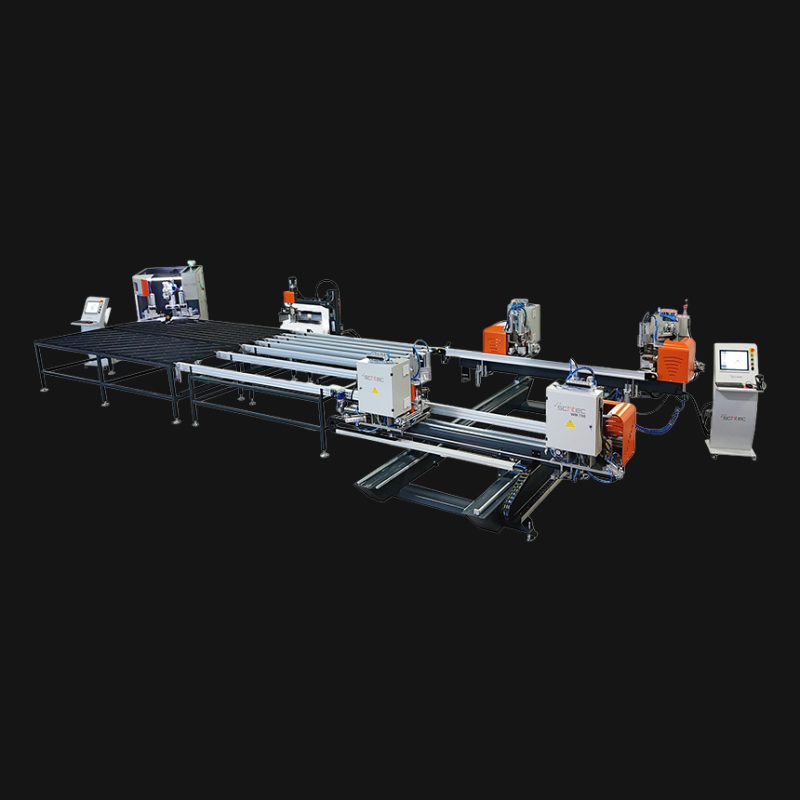

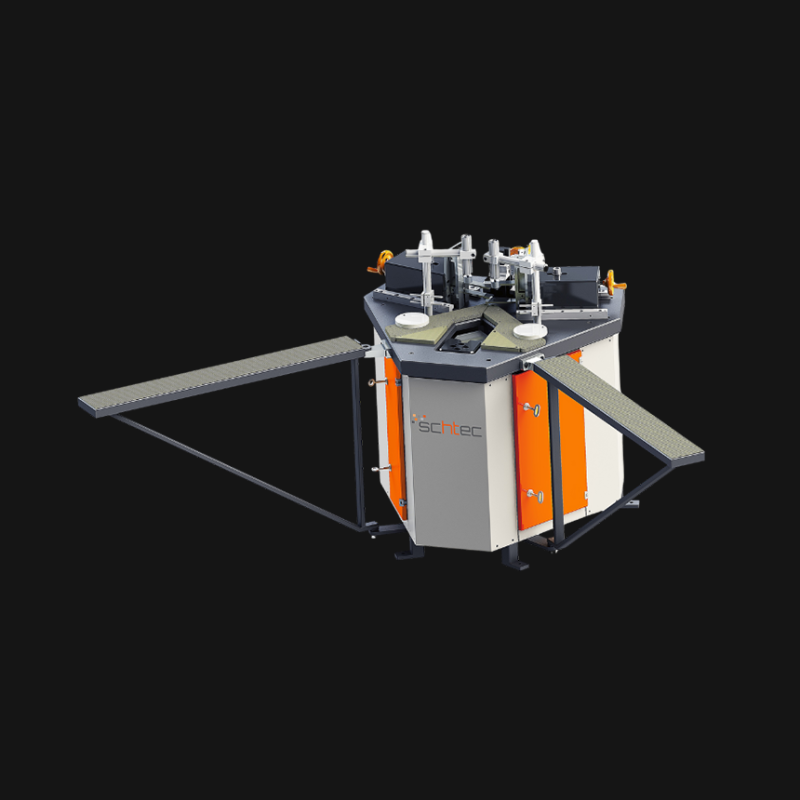

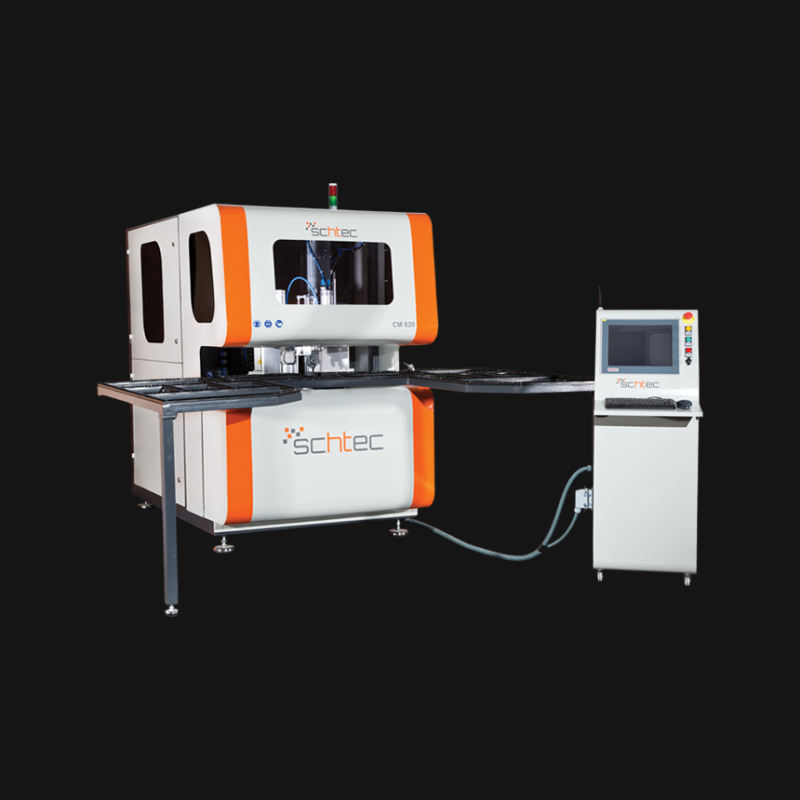

If you are ready to experience these benefits in your own facility, the next step is to find the right solution. We invite you to explore Schtec’s advanced range of PVC corner cleaning machines or contact our expert team today for a personalized consultation.