PVC Corner Cleaning Machine: What It Does and Its Advantages

The final judgment of a PVC window often rests on a single, critical detail: the corner. A flawless, seamless corner silently communicates premium quality and expert craftsmanship, creating a powerful first impression. Conversely, even a minor imperfection left from the welding process can spoil the aesthetic of the entire product. Achieving this consistent perfection is the ultimate challenge in window production, and it's where the unsung hero, the automated corner cleaning machine, proves its essential role in elevating a good window to a great one.

The Challenge: Why Manual Corner Cleaning Isn't Enough

For decades, the standard for corner finishing relied on the skilled hands of craftsmen. However, this traditional method presents critical challenges in a modern, fast-paced production environment. It is inherently inconsistent, as the final quality depends entirely on individual operator skill, focus, and fatigue. This manual process also creates a significant production bottleneck, unable to keep pace with automated welders. Most importantly, it carries the constant risk of costly mistakes, where a single slip of a tool can scrap an entire frame, wasting both time and materials.

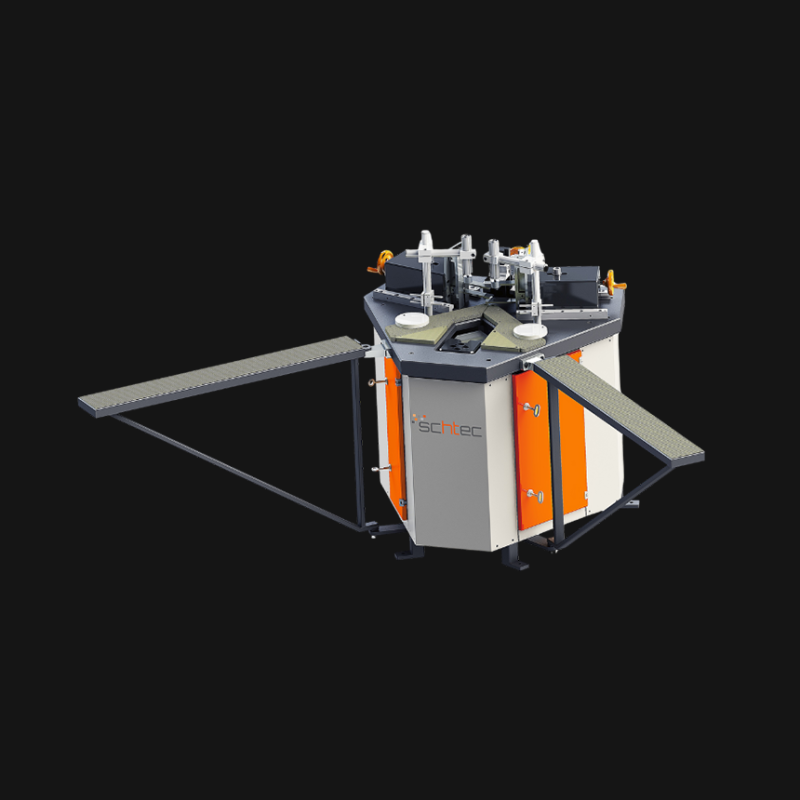

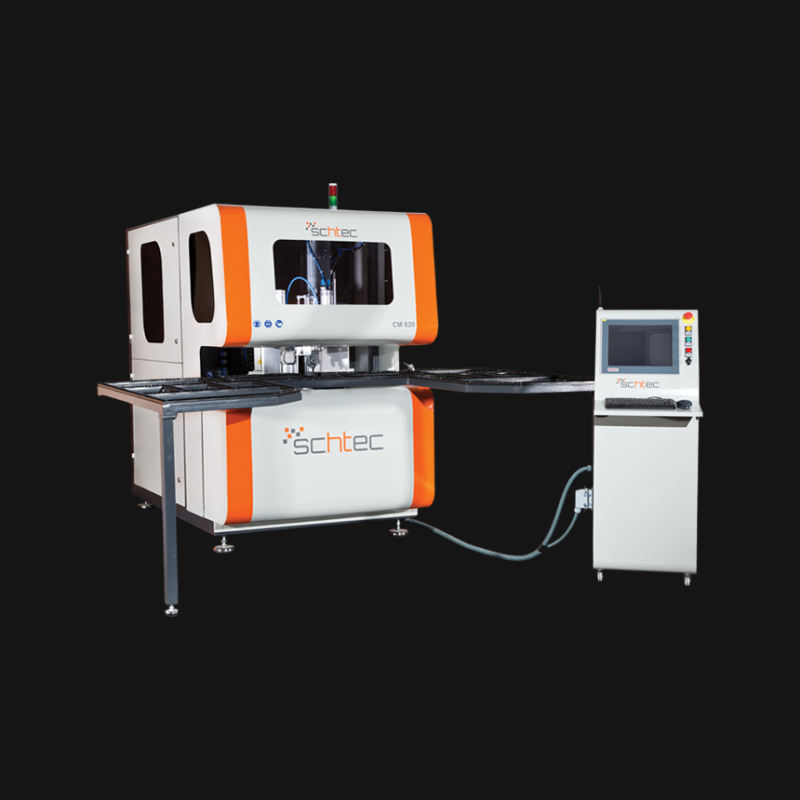

What Exactly is a PVC Corner Cleaning Machine?

A PVC corner cleaning machine is a specialized, automated solution designed to address the challenges of manual finishing. Its core function is to meticulously remove the excess material, known as a weld seam, that is created when two PVC profiles are thermally welded together. Using a sophisticated system of precision knives and milling cutters, the machine automatically cleans the top, bottom, and outer corner surfaces, transforming a rough, welded joint into a perfectly smooth and aesthetically pleasing finish in just a few seconds.

How It Works: A Look Inside the Process

The operational cycle of a corner cleaning machine is a rapid and precise sequence of automated actions. First, the operator places the welded corner onto the machine's table, where it is instantly and securely locked in place by pneumatic clamps. Next, a coordinated set of tools engages; high-precision knives skim the top and bottom surfaces to cleanly slice away the weld seam, while a specialized milling cutter simultaneously cleans the outer corner contour. Finally, all tools retract and the clamps release the frame. This entire cycle, from a raw joint to a perfectly finished corner, is completed in just seconds.

The Core Advantages of Using an Automated Corner Cleaner

The automated and precise process of a corner cleaner is more than just a technical feat; it translates into powerful, tangible benefits that impact a manufacturer's bottom line. Investing in this technology enhances operations across the board, from product quality to overall profitability. Here are the core advantages:

Flawless Aesthetics and Superior Product Quality

In a competitive market, the perceived quality of a window is paramount, and nothing communicates quality more clearly than a flawless finish. An automated cleaner ensures every corner is perfectly smooth and uniform, creating a seamless transition that makes the joint look as though it were molded from a single piece of profile. This consistent, high-end finish instantly elevates your product, enhances your brand's reputation for craftsmanship, and allows you to command a premium position in the market.

Significant Boost in Production Speed and Efficiency

One of the most impactful advantages is the dramatic increase in speed. While a manual cleaning can take minutes, an automated machine completes its cycle in seconds. This eliminates a major bottleneck in the production line, allowing the finishing stage to keep pace with welding machines. This efficiency translates directly into higher throughput, enabling you to manufacture more units per shift, take on larger projects, and meet customer deadlines with confidence.

Consistency and Elimination of Human Error

Even the most skilled operator is subject to variability from factors like fatigue or distraction. A machine has no such variables and performs the exact same precise movements every time. This robotic precision guarantees a level of consistency that is unattainable manually, ensuring every window meets the same high standard. It also eliminates the risk of costly errors, such as gouging a profile, which leads to wasted materials and time.

Reduced Material Waste and Long-Term Cost Savings

Every frame scrapped due to a cleaning error is a direct financial loss. By virtually eliminating these mistakes, an automated cleaner significantly reduces material waste. The savings also extend to labor, as the need for time-consuming rework is removed. When you combine savings from reduced waste, eliminated rework, and higher throughput, the financial case becomes clear. The machine is a strategic investment with a clear and measurable return on investment (ROI).

Enhanced Durability and Structural Integrity

A corner's quality goes beyond aesthetics; it includes its structural strength. An automated cleaner is programmed to remove only the excess weld seam, preserving the profile’s original wall thickness and structural integrity. This controlled process maintains the maximum strength of the weld, contributing to the overall rigidity of the frame. The result is a more durable and reliable long-term product, leading to greater customer satisfaction and fewer warranty issues.

Choosing the Right Machine: Key Features to Look For

Once you decide to invest in a corner cleaning machine, the next step is selecting the right model. Not all machines are created equal, and focusing on a few key areas will help you make a wise choice for your business.

Axis Control and Capability: Machines are often described by their number of axes. A higher number generally provides greater flexibility to clean complex profile shapes and intricate angles. Assess the types of profiles you use to determine the level of capability you require.

Quality of Tooling: The quality of the cutting knives and milling tools is critical for a clean finish and long service life. Look for machines that use high-quality, durable steel. If you work with laminated or foiled profiles, ensure the machine has special knives designed to clean them without causing any damage to the delicate surface.

Control System and Software: A modern machine should feature an intuitive, user-friendly control system, ideally with a touchscreen. The ability to easily create and save programs for different profile systems is a massive advantage that saves time and reduces operator errors.

Build Quality and Reliability: Examine the machine’s overall construction. A robust, heavy-duty frame reduces vibration and increases precision. The use of high-quality pneumatic and electronic components from reputable brands is a strong indicator of the machine's long-term reliability.

After-Sales Support: Your relationship with the manufacturer doesn't end at delivery. Ask about the availability of technical support, spare parts, and training programs. A strong support network is one of the most valuable features a manufacturer can offer to minimize downtime.

Conclusion: A Smart Investment for Modern Window Manufacturers

As we've explored, the automated PVC corner cleaning machine is far more than just a convenient tool; it is a fundamental component of any modern, efficient, and quality-driven manufacturing operation. It directly solves the core challenges of manual finishing by delivering powerful advantages in aesthetics, speed, consistency, and long-term cost savings, transforming a critical production step into a reliable, industrial-grade process.

Making the right equipment choices is key to future-proofing your business and maintaining a competitive edge. If you are ready to enhance your product quality, increase your production capacity, and improve your bottom line, we invite you to explore Schtec’s range of advanced solutions. Contact our team of expert consultants today to find the perfect machine to drive your business forward.