Buyer’s Guide: How to Choose the Right Corner Cleaning Machine

Investing in a PVC corner cleaning machine is a significant decision that will impact your production quality and efficiency for years to come. The market offers a wide range of models, and choosing the right one requires looking beyond the price tag to understand which features will truly benefit your specific operational needs. This guide will walk you through the key factors to consider to ensure you make a smart, informed investment.

Assess Your Production Needs: Capacity and Profile Types

Before looking at any machine, first look at your own production.

Production Volume: How many windows do you produce per shift? A small-scale workshop has different needs than a high-volume industrial facility. Be realistic about your current and projected future capacity to choose a machine that can keep up.

- Profile Complexity: Do you primarily work with standard, white PVC profiles, or do you also process a variety of complex, laminated (foiled), or acrylic-coated profiles? Handling delicate, colored surfaces requires specialized tools to prevent scratching or damage.

Key Technical Features to Evaluate

Once you know your needs, you can evaluate the technical specifications of different machines.

Number of Axes: Machines are often described by their axis count (e.g., 2-axis, 4-axis). A higher number of axes provides greater flexibility to clean complex shapes and angles automatically. For high-variety production, a 4-axis machine is often a better long-term investment.

Quality of Tooling: The knives and milling cutters are the heart of the machine. Ask about the quality of the steel used. High-quality tooling stays sharp longer, provides a cleaner cut, and reduces replacement costs. Crucially, confirm that the machine has dedicated knives for laminated profiles if you work with them.

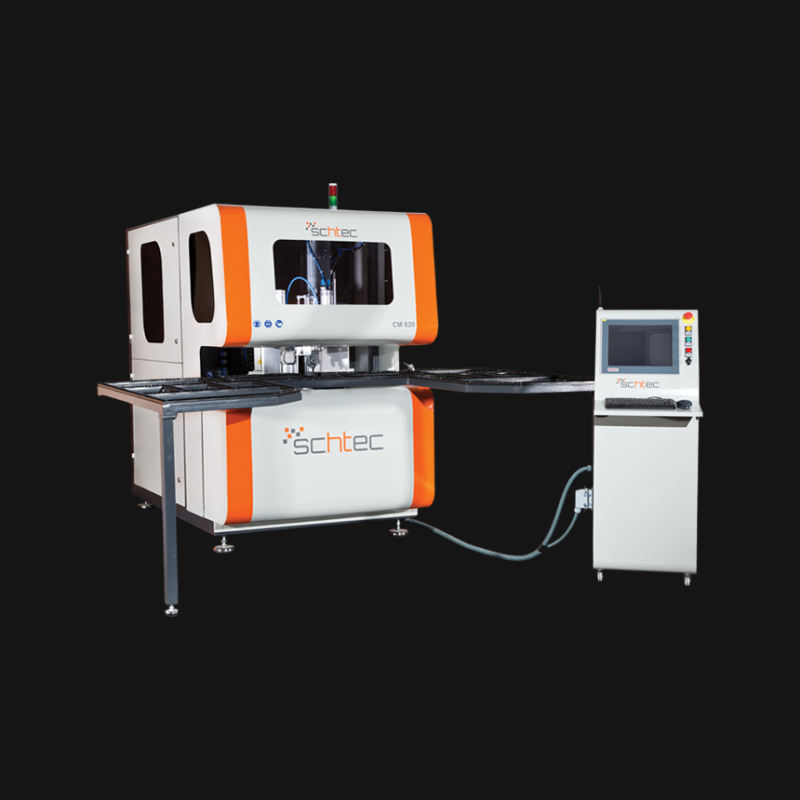

Control System and Software: A modern machine should have an intuitive, user-friendly control system, ideally with a touchscreen interface. The ability to easily create, store, and recall cleaning programs for different profile systems is a massive advantage that saves time and minimizes operator errors.

Beyond the Machine: Build Quality and Support

The machine itself is only part of the equation.

Build Quality and Reliability:

A heavy, robust frame is not just for show; it minimizes vibrations, which leads to greater precision and a longer machine life. Inquire about the brands of the pneumatic and electronic components used. Reputable component suppliers are a strong indicator of a machine's long-term reliability.After-Sales Support and Spare Parts: Your relationship with the manufacturer shouldn't end at delivery. Ask critical questions: What does the warranty cover? How quickly can you get technical support or spare parts to minimize downtime? Is comprehensive operator training included? A strong support structure is one of the most valuable features a manufacturer can offer.

Conclusion: Making a Confident Choice

Choosing the right corner cleaning machine is about matching the right technology to your specific production goals. By carefully assessing your needs and evaluating a machine's technical features, build quality, and the support behind it, you can make a confident choice that will serve as a profitable and reliable asset for your business for many years.

If you're ready to explore your options further, the Schtec team is here to help you analyze your needs and recommend the perfect solution.