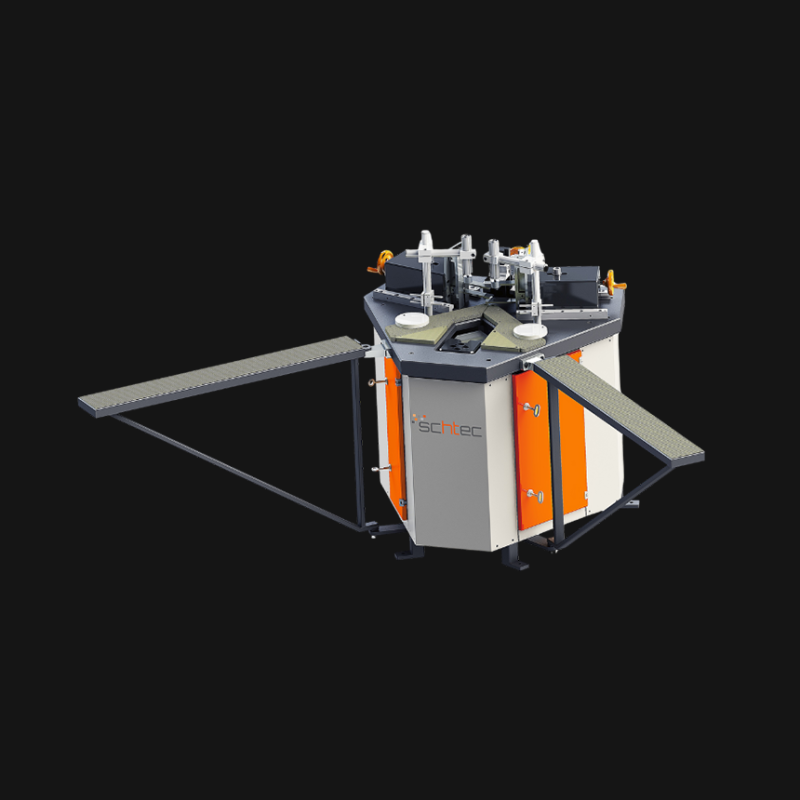

How a PVC Corner Cleaner Works: A Step-by-Step Process

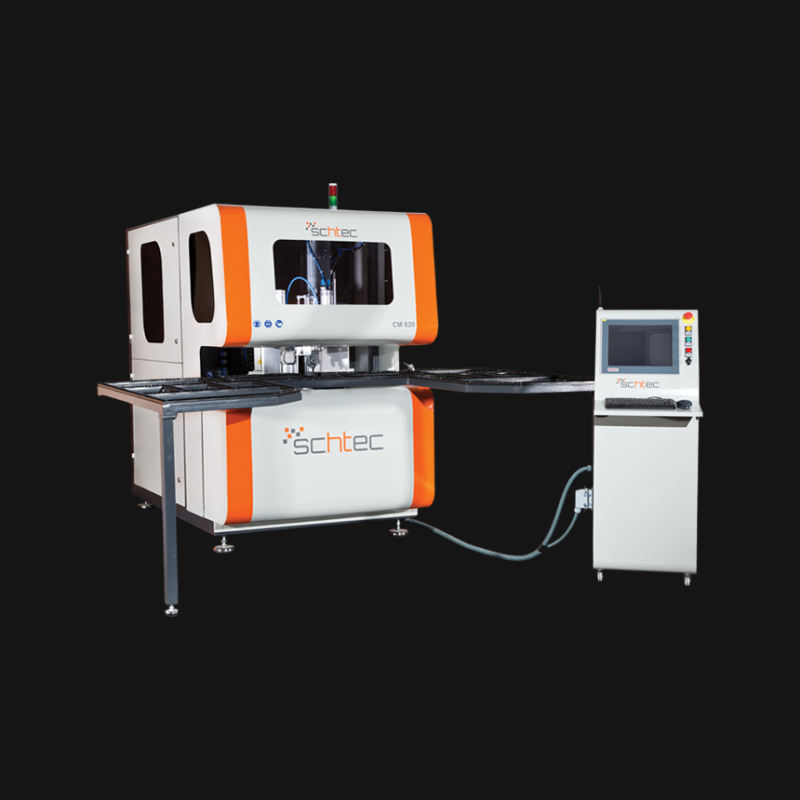

The advanced technology inside a PVC corner cleaning machine can seem complex, but its operation is a beautifully simple and logical sequence. Understanding this process reveals how automation achieves a level of precision and speed that is impossible to replicate manually. Let's break down the journey from a raw, welded joint to a perfectly finished corner, step by step.

The Four Key Stages of the Automated Cleaning Cycle

From the moment an operator places the frame on the machine, a rapid, pre-programmed cycle begins. This cycle can be understood in four distinct stages.

Step 1: Secure Positioning and Clamping

The process begins with precision placement. The operator places the corner of the freshly welded PVC frame onto the machine's table. Automatic sensors detect its position, and a powerful pneumatic clamping system engages, locking the frame securely in place. This rigid, immovable hold is the foundation for the entire cleaning cycle, as it prevents any vibration or movement that could compromise the precision of the tools.

Step 2: Precision Cleaning of Top and Bottom Surfaces

With the frame secured, the first set of tools actuates. A pair of precisely calibrated, razor-sharp knives move across the top and bottom flat surfaces of the profile. They are designed to skim the surface and cleanly slice away the raised welding seam, leaving a perfectly smooth and flush finish without scratching or damaging the original profile texture.

Step 3: Flawless Finishing of the Outer Contour

Once the flat surfaces are clean, a different tool takes over for the outer edge. A high-speed milling cutter, which is custom-shaped to match the specific decorative contour of the profile, travels along the corner's outer radius. It mills away the remaining weld material, ensuring the corner’s curve is flawless, smooth, and geometrically true to the profile's intended design.

Step 4: Ejection and Cycle Completion

With all cleaning operations finished, the knives and cutters automatically retract to their starting positions, and the pneumatic clamps release the frame. The operator can now remove the perfectly finished corner. The entire multi-stage process, from loading to completion, is typically finished in just 15 to 30 seconds, allowing for a continuous and highly efficient production flow.

A Guarantee of Speed and Precision

This step-by-step process illustrates that a corner cleaning machine doesn't just perform a task; it executes a flawless, repeatable engineering sequence. Each stage is optimized for speed, accuracy, and quality, removing the variables and errors inherent in manual labor. It's a guarantee that the last corner of the day will be identical to the first.

Now that you understand how our machines achieve such perfect results, the next step is learning how to select the right one for your specific needs. Look out for our upcoming article, the Buyer's Guide to Choosing the Right Corner Cleaning Machine.