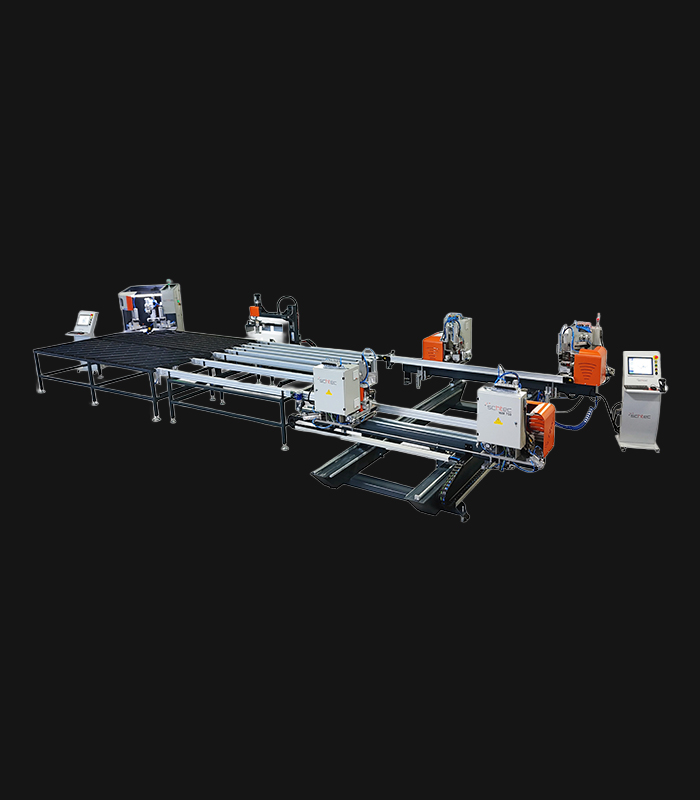

SSL 1 Four Head Welding & CNC Corner Cleaning Line

Fully automatic PVC window/door production. Simultaneous 0.1mm 4-corner welding & CNC cleaning. High-speed (400+/hr) with PID & PC control.

SSL 1 Technical Specifications

WM 740 Four Head Welding Machine

| Machine Name | WM 740 Four Head Welding Machine |

| Power Supply | 400 V, 3ph, 50-60 Hz |

| Power Consumption | 11.5 W, 28.75 A |

| Max. Welding Length | 3.600 mm x 2.600 mm |

| Min. Welding Length | 450 mm x 450 mm |

| Min. Welding Length (with gasket pressing) | 520 mm x 570 mm |

| Max. Profile Height | 180 mm |

| Min. Profile Height | 35 mm |

| Max. Profile Width | 120 mm |

| Air Pressure | 6-8 bar |

| Air Consumption | 70 lt./min. |

| Machine Height | 1.880 mm |

| Machine Length | 4.980 mm |

| Machine Width | 4.750 mm |

| Machine Weight | 1.920 kg |

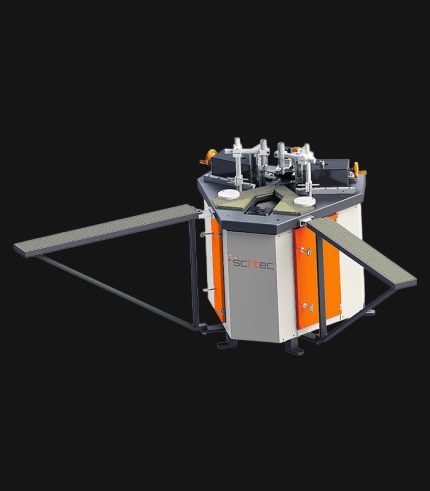

TS 820 Turning Station with the Robotics Arms

| Machine Name | TS 820 Turning Station with the Robotics Arms |

| Voltage | 400 V AC, 3 P, 50/60 Hz |

| Power Consumption | 3 kW, 7.5 A |

| Min. Outer Frame Dimension | 450 x 450 mm |

| Max. Outer Frame Dimension | 2.300 x 2.300 mm |

| Max. Profile Height | 160 mm |

| Min. Profile Height | 35 mm |

| Max. Profile Width | 130 mm |

| Machine Weight | 850 kg |

CS 810 Cooling and Buffer Station

| Machine Name | CS 810 Cooling and Buffer Station |

| Power Supply | 400 V, 3ph, 50-60 Hz |

| Power Consumption | 1,5 kW, 3 A |

| Machine Height | 1.050 mm |

| Machine Length | 3.350 mm |

| Machine Width | 2.740 mm |

| Machine Weight | 315 kg |

CM 620 CNC Corner Cleaning Machine

| Machine Name | CM 620 CNC Corner Cleaning Machine |

| Voltage | 400 V AC, 3 P, 50/60 Hz |

| Power Consumption | 7 kW, 18 A |

| Air Pressure | 6-8 bar |

| Air Consumption | 110 lt./min. |

| Saw Blade Details | Ø 250 x Ø 30 x 3.2 mm, Z=80 |

| Saw Blade rpm | 5.200 rpm |

| Drillers rpm | 14.000 rpm |

| Max. Axes Speed | 45 m./min. |

| Max. Outer Frame Dimension | Limitless (Automatic Mode: 2.300 x 2.300 mm) |

| Min. Outer Frame Dimension | 380 x 380 mm (Automatic Mode: 450 x 450 mm) |

| Max. Profile Height | 160 mm (Depending on profile type, different regions can be cleaned) |

| Min. Profile Height | 35 mm |

| Max. Profile Width | 130 mm |

| Machine Height | 1.900 mm |

| Machine Length | 2.150 mm |

| Machine Width | 1.250 mm |

| Machine Weight | 960 kg |

| Tool Count | 12 pieces |

| Capacity | 400–440 frames / 8 hours (based on 1 corner cleaning time) |

SSL 1 Four Head Welding and CNC Corner Cleaning Line

Standard Features

SSL 1 Four Head Welding and CNC Corner Cleaning Automation Line

- An integrated system which consists of a WM 740 four point welding machine, a CS 810 cooling and buffer station, a TS 820 Robotics design turning station and a CM 620 CNC Corner Cleaner

- All process is controlled by industrial PC systems from welding to cooling,to turning and finally to cleaning

WM 740 Four Head Welding Machine

- Welds four corners of PVC profiles simultaneously at 90 °with high sensitivity and strength

- Beckhoff brand, high performance industrial PC operated by Windows XP Embedded. Fanless motherboard system works between 0°C – 55°C, and it comes with a 15” touch screen display

- Data transfer via ethernet network connection, wireless network connection or USB interface

- Welding parameters are defined by the user for every individual profile(up to 10,000 profiles)

- Welding temperature, melting and welding times can be adjusted individually for each profile type.

- All machine axes are moved by hardened steel ball screw which provides accuracy and durability.

- PC controlled (PID) heat control system to obtain strong welding results in compliance with standards.

- Summer / winter working mode is automatically selected,so the temperature adjustment is done easily

- Horizontally placed strong mechanical heating plates distribute heat homogeneously without being affected from difficult working conditions.

- Easy and fast change for teflons by specially designed roll up teflon system.

- Easy and fast change for welding moulds

- Works effectively by compressed air supplied to the system

- White or colour profiles can be weld with the same sensitivity

- Central lubrication system minimizes maintenance time

- Reports can be created for daily, weekly, monthly and annual production

- Light barriers and safety equipment confors to CE machine design with full security

- Stable and accurate data transfer between this machine and the CNC corner cleaning machine via Industrial quality Ethernet connection

- All the error messages and system status can observed on screen by HMI software program developed by the Schtec software department

- Service to the entire automation system,trouble shooting and fault removals can be done by remote connection

TS 820 Turning Station with the Robotics Arms

High speed and high accuracy turning operation via a robotic system with strong and fast mechanical turning arms

- Stable turning process with highly durable turning arms

- Turning speed calculation is done automatically for each frame’s geometric shape, reinforcement steel weight and all other factors included.

- All machine axis are moved by hardened steel rack and pinion gear system which provides accuracy and durability

- Turning robot spends the minimum energy and the least amount of time by synronochizing its actions with the CNC machine’s fence system.

- Its compact design allows it to occupy the smallest working area possible, which is 12 m² less than its competitors.

- Turning time is 1 second for small frames and between 1,5 – 4 seconds for all other sizes.

CS 810 Cooling and Buffer Station

- Works between a corner cleaner and a welding machine.

- Provides cooling time for the profiles coming from the welding machine prior to sending them the corner cleaning machine.

- Cooling time is set through the welding machine’s control panel.

- Helps increase the production capacity by storing the profiles coming from the welder before sending them to the corner cleaner.

CM 620 CNC Corner Cleaning Machine

- High speed and accuracy corner cleaning with Servo System controlled 2 Axes

- Automatic knife selection for selected profile foil type (colour / white)

- High quality corner cleaning result through durable special knife and bit designs

- High quality cleaning results on surfaces by automatic measurement system

- Industrial PC Based Control System (Beckhoff)

- Remote desktop connection by way of Wifi or Network connection

- File transfer by USB or network

- Easy programming support via DXF,DWG file extensions

- Central lubrication system for all bearings, axis and sliding bearings

- 15” TouchScreen

- High performance industrial PC working between 0C – 55C with operating system Windows XP Embedded and fanless design

- All alarm messages are shown on the machine interface thanks to software which was developed by SCHTEC Software R&D Department.

- By way of using private remote desktop connection, which was developed by SCHTEC Software R&D Department, expert service technicians can connect machine automation system and machine interface for fixing or determine problems.

Optional

WM 740 Four Head Welding Machine

- Gasket pressing system

- Barcode reader

- Welding moulds

CM 620 CNC Corner Cleaning Machine

- Additional tool for sliding frames inside surface cleaning

- Additional tool for monoblock frames inner surface cleaning

Schtec SSL 1 is a fully automatic welding and CNC corner cleaning line designed for PVC window and door production. It welds all four corners simultaneously with 0.1 mm precision, ensuring fast and high-quality output. After welding, the frame is automatically rotated and cleaned by CNC blades.

With PID heat control, industrial PC management, and a capacity of 400+ frames per hour, SSL 1 delivers low error rates and high speed. Its automatic turning and cleaning functions minimize manual intervention, boosting efficiency.

The SSL 1 line is an ideal automation solution for PVC window and door manufacturers.

Four Head Welding & CNC Corner Cleaning Line for PVC

SCHTEC SSL 1 automates 4-corner PVC welding & CNC cleaning. 400+ frames/hour with PID control, HMI interface & remote access. Maximize your output today!

FAQ

What is a welding automation line and what is it used for?

SCHTEC welding automation lines fully automate all stages of PVC window and door production, from frame welding to corner cleaning. With components like SSL 1, WM 740 welding, CS 810 cooling, TS 820 robotic turning, and CM 620 CNC cleaning units, the system ensures 0.1 mm precision and speeds up production.

What are the advantages of a PVC window production line?

SCHTEC automation lines offer up to 30% increased speed and a capacity of over 400 frames per hour. With PID heat control, industrial PC, and HMI interface, they reduce error rates. The SSL 1 system, used in over 65 countries, enables digital production through remote access and automatic reporting.

Which profiles are compatible with the CNC corner cleaning line?

SCHTEC automation lines are compatible with all standard PVC profiles. SSL 1 and SSL 1 / SP can process various profile types with 0.1–0.2 mm precision. Automated turning and cleaning ensure fast and accurate production across different frame sizes.

How is a SCHTEC automation line installed?

SCHTEC provides on-site installation and operator training after delivery. Our 7-person service team supports from our 9,000 m² facility, offering centralized lubrication, remote connectivity, and 24/7 technical support to guarantee uninterrupted production.