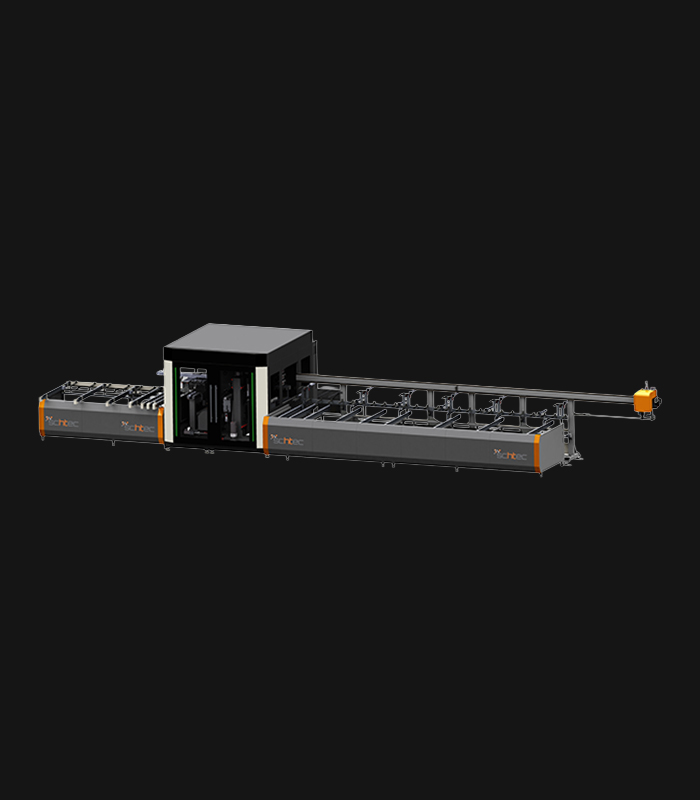

MCALS 650 Profile Machining & Cutting Center

SCHTEC MCCALL’S 650: 24-axis CNC for aluminum profiles up to 7m. Ø600 mm & Ø400 mm saws, 0.1° precision, 16-tool milling. IoT-ready, 15” touchscreen, 40 kW.

MCALS 650 Technical Specifications

| Voltage | 400 V, 3 Ph, 50-60 Hz |

| Power Consumption | 40 kW, 100 A |

| Spindle Speed | 24,000 rpm |

| Spindle Power | 4.5 kW, S6 |

| Collet Type | ER 25, ER 25 mini |

| Min. Profile Width | 35 mm |

| Maximum Tool Count | 16 units |

| Max. Profile Height | 240 mm |

| Max. Profile Width | 300 mm |

| Max. Profile Length | 7,000 mm |

| Air Pressure | 7 bar |

| Air Consumption | 3,600 l/min |

| Machine Height | 2,780 mm |

| Machine Length | 16,780 mm |

| Machine Width | 4,180 mm |

| Machine Weight | 9,450 kg |

MCALS 650 Profile Machining & Cutting Center

Standard Features

- On Aluminium profiles, all drilling, milling, marking, and cutting processes are carried out under computer control.

- Operates with high efficiency with 24 high-precision axes controlled servo motors,

- Capacity for loading 6 profiles, capable of loading profiles up to 7 meters in length.

- Automatic cutting with 0.1° precision using a Ø600mm vertical saw, servo motor controlled.

- Automatic cutting with 0.1° precision using a Ø400mm horizontal saw, servo motor controlled.

- Servo-controlled gripper that can rotate 0° to 180°.

- Capability to perform milling, drilling, and angled drainage channel operations.

- Waste collection conveyor and wasting bin inside the machine.

- PC-controlled, capable of 3+3 = 6-axis interpolation in two separate groups (Saw-CNC).

- Precision operations with 16 tools located at the milling station.

- Intermediate angle operation capability with a 4-angle servo-controlled tool.

- Height-adjustable servo-controlled clamp units in the Saw and Milling groups.

- Electronic horizontal and vertical clamp control in the saw group.

- High-performance coolant system arranged for use during profile processing.

- Low power consumption enabled by smart control technology.

- DC connection in axis drives for greater energy efficiency.

- Uninterruptible Power Supply (UPS).

- High-performance industrial PC with a 15″ touchscreen, Windows 10 Embedded OS, operates fanless between 0°C and 55°C.

- Industrial PC Based Servo Control System (Beckhoff)

- Online diagnostic and troubleshooting via user friendly interface.

- Compatible with IoT & Industry 4.0.

- User-friendly interface and online diagnostics and fault detection via I/Q and pneumatic system BUS control.

- Ability to upload job files via USB or Network and connect remotely to the machine.

- Centralized lubrication system that simplifies machine maintenance.

- Fast and efficient remote service via online connection.

Optional

- Option: 3-axis servo-controlled profile fitting unit.

The SCHTEC MCALS 650 is a fully automated production center that integrates cutting, drilling, milling, and marking of aluminum profiles. With 24-axis servo control and vertical Ø600 mm and horizontal Ø400 mm saws, it delivers 0.1° precision. It supports profiles up to 7 meters in length and includes a 16-tool milling unit, completing all processes with minimal operator intervention. A Windows 10 Embedded-based 15” touchscreen, IoT compatibility, and Industry 4.0 readiness make it ideal for smart manufacturing. Its 40 kW motor delivers maximum efficiency for industrial-scale production.

PVC & Aluminium Profile Machining and Cutting Center

SCHTEC SMC 360, MCCALL'S 650, SVMC 120: CNC for PVC & aluminum, 0.1° precision, 6.5m capacity. Automate window & door production. Get a quote!

FAQ

What is a PVC profile machining center and what is it used for?

SCHTEC PVC profile machining centers combine cutting, drilling, milling, and marking processes for PVC and aluminum profiles within a single automated system. Models like SMC 360 and MCALS 650 operate with 0.1° precision, enhancing production speed and minimizing material waste. They are used in the manufacturing of windows, doors, and façade systems.

What are the advantages of an aluminum cutting machine?

SCHTEC aluminum cutting machines offer 0.1° precision with CNC-controlled servo motors. Energy-efficient motors, centralized lubrication, and a 15” touchscreen HMI ensure low maintenance and high productivity. Models like SMC 320 and SVMC 120 reduce production time by up to 20% and are used in over 65 countries.

Which profiles are compatible with CNC profile machining machines?

SCHTEC machines are compatible with all standard PVC and aluminum profiles. Models like SMC 310 and MCALS 650 can process profiles up to 6.5–7 meters in length. With automatic loading and multi-axis control, they provide fast changeovers and precise operations for different profile types.

How is the SCHTEC profile machining center installed?

SCHTEC provides on-site installation and operator training after delivery. Our 7-person service team, based in a 9,000 m² facility, offers remote service for Industry 4.0-compliant machines. We guarantee uninterrupted production with 24/7 technical support.